Yaa Plasma Technology Scientific Discipline Inwards Textile: A Footstep Towards The Dark-Green Surroundings (Part-2)

Thursday, 20 December 2018

Edit

Plasma Technology inwards Textile: Influenza A virus subtype H5N1 footstep towards the greenish environs (Part-2)

Arpita Kothari

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 7837-696041

Email: geniousarpita@gmail.com

Arpita Kothari

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 7837-696041

Email: geniousarpita@gmail.com

2. Plasma technologies:

2.1. Low describe per unit of measurement area mutual frigidity plasma technology:

Low-pressure mutual frigidity plasma technology is also referred to every bit vacuum plasma technology. This engineering has its root inwards the processing of semiconductor materials in addition to printed circuit boards (PCB). Soon afterwards its introduction inwards the electronics industry, the path to incorporation into the textile in addition to nonwoven sectors has been in addition to remains troublesome.

The plasma nation of a gas – also considered every bit the 4th aggregation nation of thing – tin live reached if the gas is nether sufficiently low-pressure in addition to when electromagnetic unloose energy is provided to the gas volume. Under those circumstances, the procedure gas volition live partially decomposed into radicals in addition to atoms in addition to volition also live partially ionised. Depending on the frequency of the electromagnetic energy, the describe per unit of measurement area gain inwards which equilibrium amongst a high density of charged particles is reached powerfulness live different. For the radio frequency gain (typically xl kHz or 13.56 MHz), commonly the working gas describe per unit of measurement area is kept inwards the lower 0.1 mbar range, whereas for microwave sources, a working describe per unit of measurement area betwixt 0.5 in addition to 1 mbar is oftentimes used. In social club to number the plasma handling inwards sufficiently pure procedure gas conditions, a base of operations describe per unit of measurement area inwards the lower 0.01 mbar needs to live reached. This tin live done amongst two-stage roughing vacuum pumps (rotary vane type) or amongst a dry out heart or amongst a combination of either of those pumps amongst a roots blower.

Plasma tin convey several effects to substrates, depending on the plasma fashion in addition to the procedure gases used. There are 5 major effects fine cleaning, surface activation, etching, cross-linking in addition to coating deposition.

Equipment based on this:

|

| Figure 2: Roll-to-Roll batch plasma systems. |

|

| Figure 3: True roll-to-roll spider web treatment |

2.1.1. Glow discharge:

It is the oldest type of plasma technique. It is produced at reduced describe per unit of measurement area (low-pressure plasma technique) in addition to provides the highest possible uniformity in addition to flexibility of whatsoever plasma treatment. The plasma is formed past times applying a DC, depression frequency (50 Hz) or radio frequency (40 kHz, 13.56 MHz) voltage over a pair or a serial of electrodes. (Figure A, B, C) Alternatively, a vacuum glow discharge tin live made past times using microwave (GHz) powerfulness supply.

2.2. Atmospheric-pressure mutual frigidity plasma processing technology:

Low describe per unit of measurement area plasma processing has failed to brand an affect inwards the textile sector because of a detail constraint, which is incompatible amongst industrial volume production. All the technologies developed to engagement are based on the properties of low-pressure plasmas. The procedure must conduct maintain house inwards an expensive, closed-perimeter vacuum scheme in addition to cannot live used for continuous production lines operating at room temperature, amongst machines processing cloth 2 meter broad at high speed.

To overcome these restraints, Atmospheric Pressure Plasma Techniques are beingness developed. This technique provides the highest possible plasma density (in the gain of 1 to 5 x 1012 electrons cm-3), without the associated high gas temperatures in addition to the mutual frigidity plasma chemically treats cloth in addition to other substrates without subjecting them to damaging high temperatures. The Atmospheric Pressure Plasma is a unique, non-thermal, glow-discharge plasma operating at atmospheric pressure. The discharge uses a high-flow feed-gas consisting primarily of an inert carrier gas, similar He, in addition to modest sum of additive to live activated, such every bit O2, body of water or CF4.

The evolution of 3 types of APP that conduct maintain relevance for textile handling – the Corona Discharge, the Dielectric Barrier Discharge, the Atmospheric Pressure Glow Discharge.

2.2.1. The Corona Discharge:

Corona discharges are plasmas that termination from the high electrical champaign that surrounds an electrically conductive spatial singularity when a voltage is applied. The high electrical champaign roughly the singularity, i.e. the signal of the needle or the wire, causes electrical breakdown in addition to ionisation of whatever gas surrounds the singularity, in addition to plasma is created, which discharges inwards a fountain-like spray out from the signal or wire. Plasma types are characterised, inter alia, past times the number, density in addition to temperature of the gratuitous electrons inwards the system.

The discharge is in addition to so narrow that the residence fourth dimension of the cloth inwards the plasma would live likewise brusque for commercial functioning and, inwards addition, the powerfulness score that tin live applied is extremely express past times the cross-section capacity of the wire in addition to its powerfulness to dissipate oestrus generated during treatment. Accordingly, inwards its pure form, corona is far from an ideal textile surface processing medium.

|

| Figure 4: Corona discharge |

In contrast to the asymmetry of the corona system, if a symmetrical electrode organization is prepare comprising 2 parallel conducting plates placed inwards opposition, separated past times a gap of ∼10 mm, in addition to a high voltage, 1–20 kV, is applied, the gas betwixt the plates tin live electrically broken downward in addition to a plasma discharge generated. Generally, however, that plasma takes the cast of a hot thermal plasma arc less than a millimetre inwards diameter, which jumps from 1 spot on 1 electrode plate to a spot on the opposing electrode. This is useless for textile handling in addition to would make naught except sack a hole inwards the fabric. If, however, 1 or both of the electrode plates is covered past times a dielectric such every bit ceramic or glass, the plasma finds it much to a greater extent than hard to discharge every bit an arc and, instead, is forced to spread itself out over the expanse of the electrodes to send the electrical flow it needs to survive. This type of plasma is called a Dielectric Barrier Discharge (DBD) in addition to is large area, non-thermal in addition to uniform. Because of accuse accumulation on the dielectric, this tends to neutralise the applied electrical champaign hence choking off the plasma, the DBD must live powered past times a.c. in addition to is typically driven past times high voltage powerfulness supplies running at frequencies of 1 to 100 kHz. It is denser than the corona amongst a typical gratuitous electron density of virtually 1010 electrons/cm3 but the gratuitous electrons are slightly cooler at temperatures of twenty 000 to 50 000 K. This is a much to a greater extent than attractive candidate for textile processing than the pure corona.

|

| Figure 5: Dielectric barrier discharge |

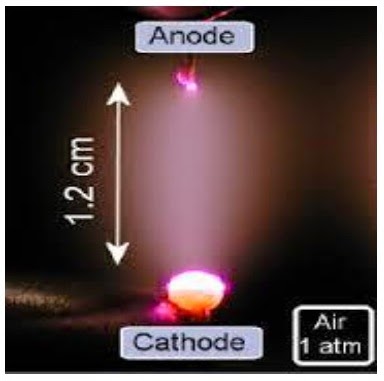

The 3rd APP type intrinsically capable of coming together the size in addition to temperature constraints needed for textile processing is the Atmospheric Pressure Glow Discharge (APGD). This is analogous inwards its fashion of generation in addition to some primal characteristics to the famous low-pressure glow discharge plasma that is the backbone of the global plasma manufacture in addition to workhorse of a dozen major industries, inwards detail the omnipresent microminiaturization industry, which would non be without the glow discharge plasma. The APGD is generated past times application of relatively depression (∼200 V) voltages across opposing symmetrical planar or curved electrodes, separated past times mm at high frequency, or fifty-fifty real high frequency, radio frequencies 2–60 MHz, much higher than the other plasma types. The electrodes are non covered past times dielectric but are bare metal, a characteristic that enables significantly higher powerfulness densities (up to 500 W/cm3) to live coupled into the discharge than tin live achieved amongst corona or DBD.

The APGD is denser than the DBD, amongst typical gratuitous electron densities of 1011–1012 electrons/cm3, but the gratuitous electrons are slightly cooler at temperatures of 10 000 to twenty 000 K. Textile handling temperatures tin run at 25–50 ºC. APGD plasma takes the cast of a bright, uniform, homogeneous glow inwards the portion betwixt the electrodes. The application of voltage betwixt metallic plates would to a greater extent than oftentimes than non termination inwards generation of a highly undesirable, real high electrical flow density in addition to hot plasma arc. By command of the interelectrode gap in addition to the frequency of the driving voltage and, inwards a higher house all, past times the role of helium every bit ∼99% of the generation gas, arcing is prevented in addition to a large volume, non-thermal plasma is generated, which is both dense in addition to a rich source of the chemic species needed to send out textile processing. This amazing gas has several exceptional properties that, inwards combination, teach far uniquely suited for the generation of well-behaved, large volume, cool plasma at atmospheric pressure. Other gases, such every bit oxygen or nitrogen, are microscopically to a greater extent than complex amongst many dissimilar energetic modes.

All inwards all, helium has been in addition to continues to live in all probability the best medium for non-thermal APP query every bit good every bit beingness technologically valuable every bit a road to useful large volume, cool plasmas.

|

| Figure 6: Atmospheric describe per unit of measurement area glow discharge |