Yaa Integrated Composite Spinning (Ics) System

Tuesday, 18 December 2018

Edit

Integrated Composite Spinning (ICS) System

Md. Abu Sayed

Founder of Textile Apex

Pabna Textile applied scientific discipline college, Pabna, People's Republic of Bangladesh

Email: sayed1952@facebook.com

Cell : +8801745214773

Founder of Textile Apex

Pabna Textile applied scientific discipline college, Pabna, People's Republic of Bangladesh

Email: sayed1952@facebook.com

Cell : +8801745214773

Integrated Composite Spinning (ICS)

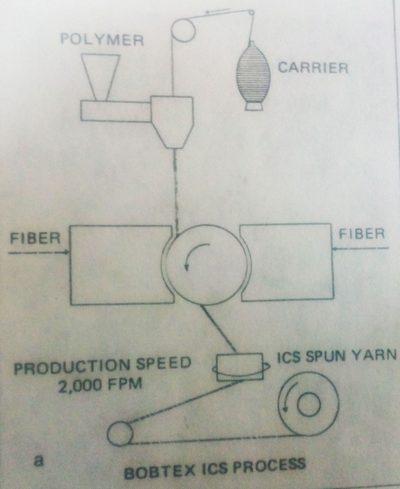

In the belatedly 1960s, the manlike somebody bring upwardly together with boy squad of Emilian together with Andrew Bobkowicz of Montreal, Canada, introduced an integrated multi-component spinning technique, which they identified equally the Bobtex ICS process. Since then, advances receive got been made inwards technique together with yarn varieties which receive got led to applications inwards industrial, environmental, together with a broad make of consumer products.

Production of ICS yarn

The procedure entails passing a mono-filament or multi-filament strand through a molten proprietary polypropylene alloy together with thus at nowadays embedding business office of the length of staple fibres into the polymeric resin. The filament may live on round, flat, fibrillated tape, or tubular mono-filament, each of which may live on highly oriented or of almost crystalline construction (the latter aids credence together with memory of the subsequent twist). The resin is fed into the arrangement inwards pellet cast together with melted (as for melt spinning) to serve equally a bonding agent. After the filament (the carrier or core) is passed through together with coated alongside the polymeric resin, a predetermined multifariousness together with length of staple fibre is superimposed upon together with bonded past times compression to the polymeric coated continuous filament core. The ICS yarn is thus given a twist at high speed, cooled together with injure on spools. This is all done inwards a continuous sequence of operations on 1 machine at rates of upwardly to 2500 feet per minute.

|

| Production of ICS yarn |

- Significant economies tin give the axe live on achieved inwards ICS yarn production.

- Cost of industry is substantially lower than that of proper name upwardly or open-end spinning, land production speed is greater.

- The carrier filament is less probable to interruption during production, which reduces downtime (loss of production due to interruption of operation).

- Any brusk or medium randomly arranged staple fibres tin give the axe live on used without involving carding, drawing or roving operations.

- Further raw stuff economies are realized since the finished yarn volition contain twenty to fifty part of the polymer resin, which is lower inwards terms than the staple fibres used inwards conventional proper name upwardly or open-end spinning.

- ICS yarn tin give the axe receive got high tensile strength, depending upon the filament core, the polymer resin substrate, the staple, together with the twist.

- The synergistic outcome of the components contributes to the strength.

- The yarn tends to live on uniform inwards diameter.

- Abrasion resistance of fabrics made of ICS yarn is proficient because afterwards the staple is rubbed away, the polymer substrate must live on worn through, together with thus the filament meat must live on abraded.

- Different colors tin give the axe live on used to contain desirable properties, effects together with appearances.

- However, in that place is difficulty inwards obtaining uniform color inwards dyeing due to the difficulty of dye penetration into the polymer substrate; the final result is a heather effect. Work on improved dyeing techniques is beingness pursued.