Yaa Hydroentanglement Bonding Procedure For Production Of Nonwoven Textile (Part-8)

Thursday, 20 December 2018

Edit

Hydro-entanglement Bonding Process for Production of Nonwoven Fabric (Part-8)

Eng Mohamed Elsharkawy

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Previous Part

CHAPTER (6)

RESULTS & DISCUSSION

RESULTS & DISCUSSION

After the experiments nosotros accept done on the geo-textile fabric, nosotros uncovering that the lawsuit of weight alter on stuff mechanical as well as filtration properties (hydraulic).

Weight of the stuff is an indicator of mechanical functioning exclusively within specific groups of textile, but non betwixt i type of structure as well as another.

Therefore, it is impossible to utilisation weight lone every bit a touchstone inwards specifying textiles for civil engineering scientific discipline use. However, inwards combination of specified factors, weight is a useful indication of the sort of production for a item purpose.

1. Fabric thickness

| 600 | 400 | 200 | Sample code |

| 3.292 | 2.875 | 1.9 | Thickness(mm) |

|

| Fig 6.1. |

- sample weight 200

- sample weight400

- sample weight600

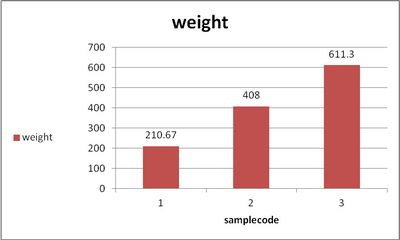

| 600 | 400 | 200 | Sample code |

| 611.3 | 408 | 210.67 | Weight(gm/mt^2) |

|

| Fig.6.2. |

At machine management

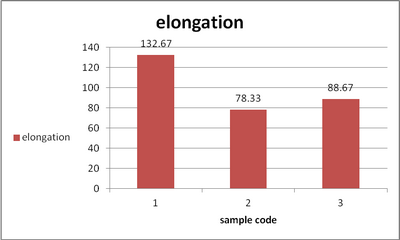

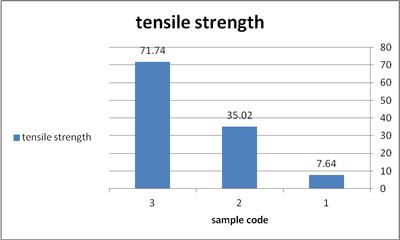

| 600 | 400 | 200 | Sample code |

| 71.74 | 35.02 | 7.64 | Tensile strength (kgf) |

| 88.67 | 78.33 | 132.67 | Elongation% |

|

| Fig.6.3 |

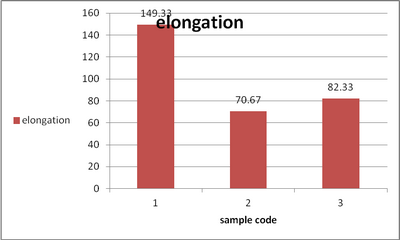

| 600 | 400 | 200 | Sample code |

| 45.84 | 30.18 | 13.98 | Tensile strength (kgf) |

| 82.33 | 70.67 | 149.33 | Elongation% |

|

| Fig.6.4 |

- As it is universally to depict the strength of the stuff as well as demo the charge at interruption as well as elongation at break.

- At tensile strength, sample code3 alongside weight 600 gives the highest strength inwards both cases (machine direction-cross machine direction) as well as at the same fourth dimension it gives the lowest value of elongation.

- But, sample code 1with weight 200 gives the lowest strength as well as the highest elongation.

| 600 | 400 | 200 | Sample code |

| 58.3 | 56.3 | 23 | Tear strength (kgf) |

|

| Fig.6.5 |

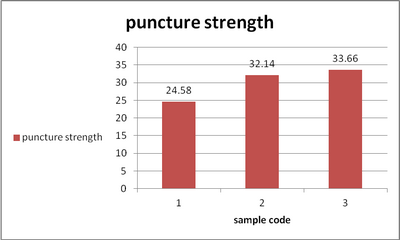

| 600 | 400 | 200 | Sample code |

| 33.66 | 32.14 | 24.58 | Puncture strength (kgf) |

|

| Fig .6.6 |

- It gives a simulation for working atmospheric condition fabric.

- At tear strength as well as puncture strength, due to fiber inwards cohesion the stuff strength is produced. So, samplecode3 alongside weight 600 gives the highest value of both as well as sample code1with weight 200 gives the lowest value of both.

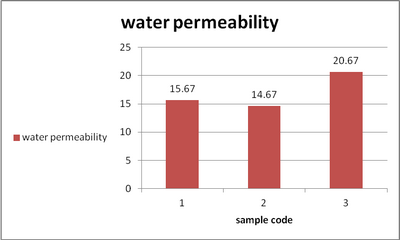

| 600 | 400 | 200 | Sample code |

| 20.67 | 14.67 | 15.67 | Water caput (cm) |

|

| Fig 6.7 |

It tin flaming vary immensely every bit it depends on the stuff construction. And it is necessary that H2O should menstruum freely through the geo-textile as well as preclude from unnecessary pressure.

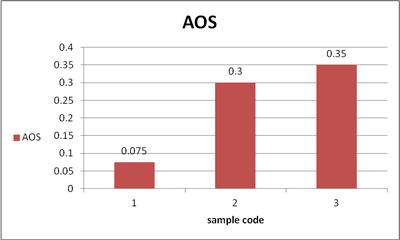

7. Apparent opening size

| 600 | 400 | 200 | Sample code |

| 0.35 | 0.3 | 0.075 | AOS (mm) |

|

| Fig .6.8 |

It gives an indication of the amount as well as size of particles which tin flaming decease through the stuff during usage.

At H2O permeability as well as apparent opening size, sample 200 tin flaming easily decease whatsoever particles as well as H2O due to its high porosity, but sample 600 is hard to permit particles or H2O to menstruum through it.

From the results, nosotros tin flaming run into that the lawsuit of weight of 3 unlike samples as well as the alter happened inwards unlike properties. The important of changing weight is changing inwards stuff structure as well as this alter the stuff properties.

In illustration of weight increase, the publish of fibers increment as well as the friction betwixt them too. This, inwards fact gives variable values for each sample.

CHAPTER (7)

CONCLUSION

CONCLUSION

In this project, nosotros report ii parts as well as they are:

- Hydro-entanglement machine for bonding non-woven.

- Experiments as well as testing geo-textiles.

So, nosotros tin flaming summarize the chief parameters inwards its blueprint every bit followed:

Parameters of H2O jets:

- Density of jets: 10 – thirty jets/cm

- Jet diameter: lxxx – 800 mm

- Pressure within the jet manifold:

- up to sixty MPa for spider web bonding (Fleissner)

- up to 25 MPa for spider web patterning (Perfojet)

- Velocity of H2O jet: 10 – 350 m/sec

Typical H2O purification organization has next stages:

- air separator,

- coarse filter, fine filter

- de-ionization unit,

- heat exchanger,

- bacteria filter.

We flora that the properties increment alongside weight increase.

Geo-textiles are used inwards civil engineering scientific discipline digging to reinforce vertical as well as steep banks of soil, to build theater bases for temporary as well as permanent roads as well as highways, to trouble footing drains, as well as then that the soil filters itself as well as prevents soil from filling upward the drainpipes as well as to preclude erosion behind stone as well as stone facing on river banks as well as the coast. They accept been developed since the mid 1970s, but the advent of knitted as well as composite fabrics has led to a revival inwards attempts to ameliorate textile structure inwards a designed fashion. Better physical properties tin flaming live achieved past times using to a greater extent than than i stuff as well as past times utilizing the best features of each.

CHAPTER (8)

REFERENCES

REFERENCES

- Pourdeyhimi B. (2005) Introducing to nonwovens, Lecture Notes of Introduction Nonwoven Products as well as Processes, North Carolina State University, NC.

- Medeiros F. J. (1997) Spun-lacing offers Utmost Versatility, American Textiles International, as well as November: 34-36.

- The Nonwovens Handbook (1988) INDA, Association of the Nonwoven Fabrics Industry.

- Vuillaume, Andre M.: Influenza A virus subtype H5N1 Global Approach to the Economics as well as End Product Quality of Spunlace Nonwovens, Tappi Journal, v.74, Aug '91, 149-152.

- White, C. F.: Hydro-entanglement Technology Applied to Wet Formed as well as Other Precursor Webs, TAPPI Nonwovens Conference, 1990, 177-187

- Jaussaud, Jean Paul: Rotary hydraulic Entanglement Technology, Nonwovens inwards Medical as well as Healthcare Applications Conference, Nov tenth -12th 1987, Brighton, England.

- Allen, Charles H., Jr.: New Development for Spun-lacing Cotton, Paper presented at Fiber Society Conference, University of Tennessee, as well as Knoxville 19th-21st Oct. 1997

- Widen, Christian B.: Forming Fabrics for Spunlace Applications, Tappi Journal, v.74, May '91, 149-153

- Information brochure for Hydro-entanglement engineering from Valmet Paper Machinery, Honeycomb Systems Inc.

- (Hsu-Yeh Huang & Xiao GAO) M. G. Kamathq, Atul Dahiya, Raghavendra R. Hegde. SPUNLACE (HYDROENTANGLEMENT)

- Spunlace Non-woven" Perfojet, Dec 1991

- " The report on the mechanical properties of spun-laced nonwoven" 16th polymer symposium Vol.9, PP 433-436.

- Christian B. Widen, "Forming fabrics for spun-lace applications" TAPPI Journal, May 1991 un.1993,

- Connolly, T.J., Parent, L.R.: Influence of Specific Energy on the Properties of Hydro-entangled Nonwoven Fabrics, Tappi Journal, v.76, Aug '93, 135-141

- http://www.atlanticbearings.co.uk/couplings.html[15]

- http://www.technologystudent.com/equip1/vert1.htm [16]

- http://www.esab-cutting.com/products/laser-cutting-process.html