Yaa Friction Spinning System

Thursday, 20 December 2018

Edit

FRICTION SPINNING SYSTEM

Bhavdip Paldiya

Dept. of Textile Technology

Sarvajanik College of Engineering & Technology, Surat, Republic of Republic of India

Cell: +91 9662020909

Email: bhavdipk9009@gmail.com

Introduction

Friction (DREF) spinning scheme is an Open-end spinning system. Along alongside the frictional forces inward the spinning zone the yarn formation takes place. The DREF scheme is used to make yarns alongside high delivery charge per unit of measurement virtually 300mpm. It make a highly uniform yarn from various stock including small or hard to grip at high production rates in addition to depression project in addition to unloosen energy expenses.

Principal of Friction Spinning System

- Fibers are delivered onto the drum surface, which transports in addition to stacks the fibers to the fiber parcel rotating betwixt 2 surfaces moving inward reverse directions.

- The fibers wrap roughly the parcel surface.

- wrapped fiber parcel (yarn tail) is tugged yesteryear the yarn delivery roll.

- Therefore twists yesteryear fiber organisation are generated.

- Due to dissever yarn winding in addition to method of twist insertion, it has capability to become for high production rate.

|

| Schematic representation of the friction yarn formation |

- DREF-1

- DREF-2

- DREF-3

- DREF-5

- DREF-2000

- DREF-3000

- DREF-1 friction spinning scheme was developed inward 1973 yesteryear Dr. Fehrer. A.G. of Austria.

- The fibers were opened alongside an opening roller in addition to allowed to autumn on a unmarried perforated cylindrical drum slot

- The rotation of the drum impart twist to fiber assembly.

- The ratio of perforated drum to yarn surface is rattling large, thence the drum speed tin send away live kept relatively low.

- Due to the absence of positive command over the fibers assembly, slippage occurred betwixt the fiber assembly in addition to perforated roller, which reduced twist efficiency

- Hence this evolution could non live commercialized

|

| DREF-1 friction spinning system |

- DREF-2 was exhibited inward the twelvemonth 1975 at ITMA exhibition.

- It operates on the terra firma of mechanical/aerodynamic spinning scheme alongside an internal suction in addition to same management of drums rotation.

- Drafted slivers are opened into private fibers yesteryear a rotating carding drum covered alongside saw molar type wire clothing.

- The individualized fibers are stripped off from the carding drum yesteryear centrifugal forcefulness supported yesteryear an air current from the blower.

- Fibers are transported into the nip of 2 perforated friction drums where they are held yesteryear suction helping inward the removal of dust in addition to dirt thereby contributing to production of cleaner yarn.

- The fibers are sub-sequentially twisted yesteryear mechanical friction on the surface of the drums.

- The depression yarn strength in addition to the requirement of to a greater extent than reveal of fibers inward yarn cross-section (minimum 80-100 fibers) were restricted the DREF-2 spinning alongside coarser counts (0.3-6s Ne).

|

| DREF-2 friction spinning system |

Advantages of the meat yarns produced using DREF-2 method

- Uniform breaking strength along the entire length in addition to fantabulous running properties for farther processing (weaving in addition to raschel knitting process).

- Excellent yarn regularity.

- Good adhesion of the sheath fibers to the core.

- No rewinding required due to the direct provision of the cylindrical bobbins to the weaving procedure inward a weight hit of 8 - 10 kg.

- Long, knot-free lengths.

- High weaving effectiveness, due to the eradication of thread breaks.

- High levels of surface area stability inward the finished weave.

- Retention of a textile surface character.

- Blankets for the dwelling identify application range, hotels in addition to military machine uses etc.

- Interior decoration, wall coverings, draperies in addition to filler yarn.

- Shoes, ropes in addition to industrial cable manufacturing.

- Filler cartridge for liquid filtration

- For upholstery, tabular array cloths, wall coverings, curtains, hand-made carpets, bed coverings in addition to other decorative fabrics.

- Heavy flame-retardant fabrics, conveyor belts, clutches in addition to brake linings, friction linings for automobile industry, packets in addition to gaskets.

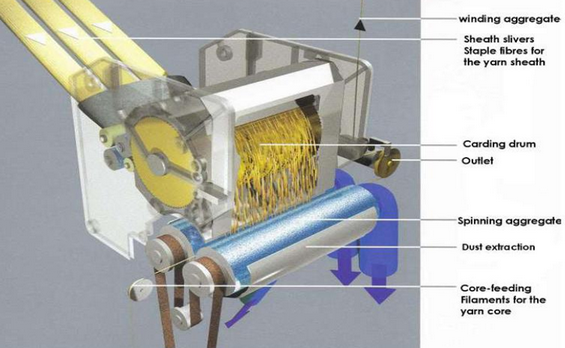

- The DREF-3 machine is the adjacent version of DREF-2 for improving the yarn lineament came to the marketplace spot inward the twelvemonth 1981.

- Yarns upwardly to 18s Ne. tin send away live spun through this system.

- This is a core-sheath type spinning arrangement.

- The sheath fibers are attached to the meat fibers yesteryear the imitation twist generated yesteryear the rotating activity of drums.

- Two drafting units are used inward this system, i for the meat fibers in addition to other for the sheath fibers.

- This scheme produces a diversity of core-sheath type structures in addition to multi-component yarns, through selective combination in addition to placement of unlike materials inward meat in addition to sheath.

- Delivery charge per unit of measurement is virtually 300 m/min.

|

| DREF-3 friction spinning system |

- Backing fabrics for printing, belt inserts, electrical insulation, hoses, filter fabrics

- Hot air filtration in addition to moisture filtration inward nutrient in addition to carbohydrate industries.

- Clutch lining in addition to brake lining for automotive industries.

- It was developed yesteryear Schalafhorst, Suessen in addition to Fehrer.

- The hit of count to live spun from this scheme is from 16’s to 40’s Ne.

- Production speed is upwardly to 200m/min.

- This spinning scheme was non commercialized due to some reasons.

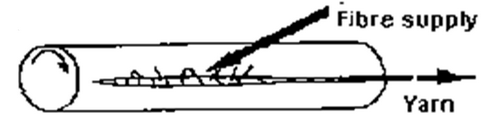

- The individualized fibers from a unmarried sliver are fed through a fiber duct into the spinning nip at an angle to the yarn axis.

- They are stretched every bit far every bit possible, when fed into the nip.

|

| DREF-5 friction spinning system |

- It is the latest evolution inward friction spinning demonstrated inward ITMA 99.

- DREF-2000 employs a rotating carding drum for opening the slivers into unmarried fibers in addition to a particularly designed scheme beingness used for sliver retention.

- The fibers stripped off from forepart the carding drum yesteryear centrifugal forcefulness in addition to carried into the nip of the 2 perforated spinning drums.

- The fibers are later on twisted yesteryear mechanical friction on the surface of the drums.

- Drums are rotates inward the same direction.

|

| DREF-2000 friction spinning system |

- Insertion of twist inward ‘S’ in addition to ‘Z’ management is possible without mechanical alterations to the machine.

- Yarns upwardly to 14.5s Ne tin send away live produced at speeds of 250 m/min.

- Reduced yarn grooming costs due to high sliver weights (card slivers).

- Dust extraction for secondary fibers.

- Low unloosen energy costs due to the purpose of alone 1 fan for 12 spinning heads.

- Feeding of all types of filaments, yarns in addition to components every bit yarn cores, inward social club to accomplish high yarn strength in addition to production speeds, voluminous yarns in addition to specific production characteristics.

- Blankets for the homes, hotels, hospitals, camping, military machine uses, plaids etc.

- Cleaning rags in addition to mops from cotton fiber waster in addition to various waste-blends

- Deco- in addition to upholstery fabrics

- Outerwear in addition to leisure-wear

- Filter cartridges for liquid filtration

- Secondary carpeting backing for tufting carpets

- Canvas in addition to tarpaulins for the military machine in addition to civil sectors

- High-tenacity meat yarn for ropes, carry in addition to conveyor belts

- Asbestos substitutes for heavy protective wearable (protective gloves, aprons etc) packing, gaskets, clutch in addition to brake-linings, flame retardant fabrics etc.

- Filter Yarns for the cable, shoe in addition to carpeting industries

- Carpet Yarns (Berber carpets, hand-woven in addition to hand-knotted carpets) in addition to filler weft yarns for carpets

- In the ITMA 2003, the kickoff world appearance of the DREF 3000 was made.

- The yarn tin send away live spun shape 0.3Ne to 14.5Ne.

- System Expansion of the range of yarn in addition to fiber utilization inward the coarse yarn count hit

- Production of both ‘S’ in addition to ‘Z’ yarns at whatsoever fourth dimension without mechanical alterations to the machine

- Reduced yarn grooming costs due to high sliver weights (card slivers)

- Higher Bobbin weights through 200mm winding traverse.

- High tenacity in addition to FR protective wearable for civil & military machine sector

- Fire blocker for the aviation in addition to contract work organisation range, cutting protection textiles (protective gloves, mail-bags, spot coverings)

- Fiber composite materials for the aviation, automotive, machinery, in addition to construction manufacture

- Tarpaulins, carry in addition to conveyor belts every bit good every bit all kinds of technical textiles

- Filter fabrics for dry out in addition to moisture filtration

- Upholstery fabrics for contact work organisation hit

- Knitting sector, elastomeric fabrics

- Outdoor textiles (eg chair in addition to dock-chair covering)

The mechanism of yarn formation is quite complex. It consists of 3 distinct operations.

- Feeding of fibers

- Fibers integration

- Twist insertion.

The individualized fibers are transported yesteryear air currents in addition to deposited inward the spinning zone.

There are 2 methods of fiber feed

1) Direct feed

Fibers are fed straight onto the rotating fiber mass that outer business office of the yarn tail.

|

| Direct feed |

Fibers are kickoff accumulated on the in-going gyre in addition to so transferred to the yarn tail.

|

| Indirect feed |

- The fibers through feed metro assembles onto a yarn core/tail inside the shear field, is provided yesteryear 2 rotating spinning drums in addition to the yarn meat is inward betwixt them.

- The shear causes sheath fibers to wrap roughly the yarn core.

- The fiber orientation is highly subject on the decelerating fibers arriving at the assembly shout out for through the turbulent flow.

- The fibers inward the friction drum receive got 2 in all probability methods for integration of incoming fibers to the sheath.

- The fiber assembles completely on to perforated drum earlier their transfer to the rotating sheath.

- Fibers are position straight on to rotating sheath.

Twist insertion

- The fibers are applied twist alongside to a greater extent than or less i at a fourth dimension without cyclic differentials inward tension inward the twisting zone.

- Therefore, fiber migration may non receive got identify inward friction spun yarns.

- The mechanism of twist insertion for meat type friction spinning in addition to opened upwardly goal friction spinning are different.

- Core is made of a filament or a parcel of staple fibers is imitation twisted yesteryear the spinning drum.

- The sheath fibers are deposited on the imitation twisted meat surface in addition to are wrapped helically over the meat alongside varying helix angles.

- It is believed that the imitation twist inward the meat gets removed i time the yarn is emerged from the spinning drums, so that this yarn has virtually twist less core.

- However, it is quite possible for some amount of imitation twist to stay inward the fact that the sheath entraps it during yarn formation inward the spinning zone.

- The fibers inward the yarn are integrated every bit stacked cone.

- The fibers inward the surface of the yarn constitute to a greater extent than compact in addition to expert packing density than the axial fibers inward the yarn.

- The Figure shown the organisation of fibers inward the DREF-3 yarn every bit stacked cone shape .

|

| Stacked conical mass of fiber |

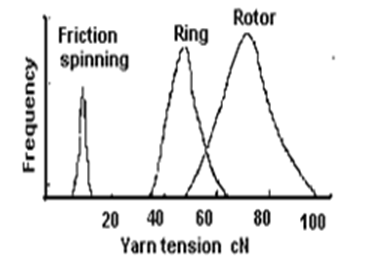

- Friction spun yarns receive got less spinning tension during the yarn formation.

- Due to less tension during the spinning the meat element tin send away live placed just at the centre of the yarn.

|

| Spinning tension for DREF band in addition to rotor yarns |

- Friction spun yarns (DREF) yarns receive got bulky appearance (100-140% bulkier than the band spun yarns)

- The twist is non uniform in addition to constitute alongside loopy yarn surface.

- Usually weak every bit compared to other yarns.

- The yarns possess alone 60% of the tenacity of ring-spun yarns in addition to virtually 90% of rotor spun-yarns.

- The breaking elongation of ring, rotor in addition to friction spun yarns is equal.

- Depending on the type of fiber, the differences inward strength of these yarns differ inward magnitude.

- 100% polyester yarns-strength deficiency is 32%

- 100% viscose yarns-it ranges from 0-25%

- In polyester-cotton blend, DREF yarns perform amend than their ring-spun counterparts.

- 70/30% blend yarn-superior inward strength yesteryear 25%

- DREF yarns are inferior inward price of unevenness, imperfections, strength variability in addition to hairiness.

- The friction spun yarns are to a greater extent than hairy than the band spun yarns

- DREF yarns are most irregular inward price of twist in addition to linear density spell band spun yarns are most even.

If i yarn creates out of 2 or to a greater extent than unmarried yarn components is called hybrid yarn. Hybrid yarns are used:

A. For reinforced plastics

Properties of the yarn

- Core/Sheath construction alongside centric spot of the reinforcing filament

- Zero twisted reinforced filament gives best strength resultant

- Definable fiber matrix proportion

- Protection of the reinforcing filament through the sheath fibers

Yarn Properties

- Huddle fiber organisation for best filter activity

- High elongation values

- Long yarn length knotless

- Uniform yarn alongside high tensile strength

Yarn properties

- Flame resistance

- High temperature resistance

- High tear abrasion resistance

- Good wearing comfort

- Good aid properties

- Skin friendly

Yarn Properties

- Steady high tensile strength

- High uniformity of the yarn

- Long knotless length of the yarn

- Good non-rotating properties

- High chemic resistance

- Good thermal transfer

- Dust costless production

- Electric insulation

- Good dimension stability for carpets

Yarn properties

- High yarn book

- Good temperature resistance

- High tensile strength

- Low elongation

Yarn properties

- High cutting resistance

- Good wearing comfort

- High dimension stability

- It tin send away spin yarn at rattling high twist insertion rates (ie.3,00,000 twist/min).

- The yarn tension is practically independent of speed in addition to thence rattling high production rates (up to 300 m/min) tin send away live attainable.

- Improved dirt particle retentiveness in addition to upwardly to twice the filter service life.

- Considerable reduced yarn production costs (up to 50%) due to lower yarn mass requirement, lower grooming costs, lower spinning costs in addition to lower personnel expenses.

- Low yarn strength in addition to extremely miserable fiber orientation made the friction spun yarns rattling weak.

- The extent of disorientation in addition to buckling of fibers are predominant alongside longer in addition to finer fibers.

- Friction spun yarns receive got higher snarling tendency.

- High air consumption leads to high might consumption.

- The twist variation from surface to meat is quite high; this is some other argue for the depression yarn strength.

- It is hard to concord spinning weather condition every bit constant.

- The spinning scheme is express yesteryear drafting in addition to fiber transportation speeds.