Yaa Character Command Organization For The Clothe Manufacture (Domestic / Export)

Thursday, 20 December 2018

Edit

QUALITY CONTROL SYSTEM FOR THE APPAREL INDUSTRY – (DOMESTIC / EXPORT)

R.S.BALAKUMAR

M.A.(SOCIOLOGY ), M.L.M.(Labour Management), Pursuing MBA(EXECUTIVE) inwards (FASHION-TECH), MISTE.,

Chennai, Republic of Republic of India

Cell: +91-9283182955

Email: rsbalakumar1953@gmail.com

QUALITY SYSTEM REQUIREMENTS

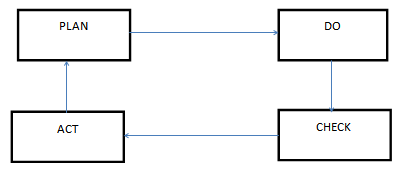

The Quality System Requirements are based on the regulation of PDCA Cycle.

|

| PDCA Cycle |

- Understanding the customers character requirements

- Organizing & grooming quality control subdivision

- Ensuring proper period of time of character requirements to the QC subdivision

- Ensuring proper period of time of character requirements to the production Department

- Establishing character plans, parameters, inspection systems, frequency, sampling techniques, etc..

- Inspection, testing, measurements every bit per programme

- Record deviations

- Feed dorsum to production Department

- Plan for farther improvement

|

| Quality Control System for the Apparel Industry |

ESTABLISHING THE QUALITY REQUIREMENTS

The starting fourth dimension pace for character command is to understand, found & bring the customers character requirements. This involves the next steps.

PRE PRODUCTION INSPECTION

The next parameters & defects are checked prior to cutting.

Many of the of import parameters of Pre-productions, during productions & Final inspection parameters. This is to ensure that incorrect or major defective garments are non packed.

FINAL INSPECTION

A. PACKING & ASSORTMENT

Compare the garment measurements against the Customers Measurement Charts. Following are the to a greater extent than or less of the of import garments measuring aspects to survive considered.

H5N1 for sure proportion of defective volition e'er occur inwards whatsoever manufacturing process. If the percent does non laissez passer on a for sure limit, it volition survive economical to permit the defective to larn through instead of screening the entire lot. This boundary is called the “Acceptable Quality Level” (AQL)

Considering the practical & economical aspects, Sampling Techniques are adopted to bring or turn down a Lot on the Blue Planet of the Samples drawn at Random from the lot. It has been found in addition to accepted that a scientifically designed sampling & inspection programme protects a Manufacturer too every bit the Buyer economically.

American Military standards known every bit MIL-STD-105A to 105E is accepted worldwide for sampling sizes. It has the next sample size levels. Normally for Garment Industry 105D or 105E are followed.

ECOLOGICAL PARAMETERS

Now all the Customers are bespeak for Ecological Parameters. Now European Buyers are stressing this. Following are master copy Ecological Parameters to survive considered.

Quality Control System inwards Apparel Industry plays an vital locomote in addition to volition construct upward skillful human relationship betwixt Buyer in addition to manufacturer. Now a days customers prefer to purchase the goods to satisfy their requirements. To construct upward skillful human relationship betwixt manufacturer in addition to customer, character command organisation is e'er helping every bit a wonderful dyad betwixt them.

The starting fourth dimension pace for character command is to understand, found & bring the customers character requirements. This involves the next steps.

- Getting customers specifications regarding the character

- Referring our past times performance

- Discussing alongside the Quality Control Department

- Discussing alongside the production Department

- Giving the Feed Back to the customers

- Receiving the revised character requirements from the customers

- Accepting the quality parameters

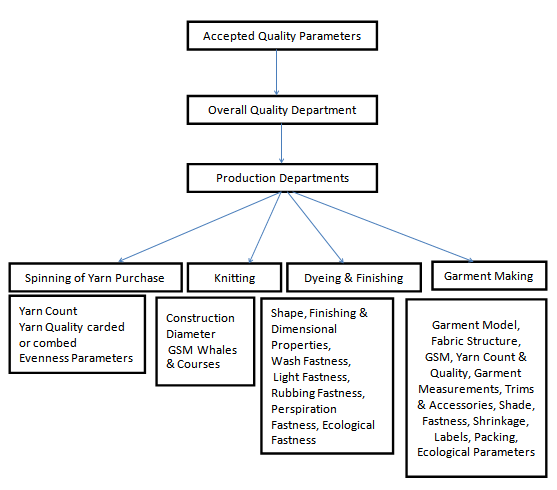

FLOW CHART FOR SPECIFICATIONS & QUALITY PARAMETERS

The next levels are discussed at the Garment Making Department assuming that this subdivision is receiving the make to cutting dyed & finished fabrics from the Dyeing & Finishing Department.  |

| Flow nautical chart of quality |

VARIOUS LEVELS OF INSPECTION & QUALITY CONTROL

PRE PRODUCTION INSPECTION

The next parameters & defects are checked prior to cutting.

- Shade Matching

- Fabric Construction

- GSM (grams per foursquare meter)

- (Whales & Courses if required)

- Diameter

- Dyeing Levelness

- Ecological parameters if required

- Softness

- Shrinkage

- Matching of Rib, Collars & Cuffs

- Fabric Holes

- Vertical & Horizontal Stripes

- Knitting defects such every bit missing loops, sinker lines, etc.

- Bowing

- Skewing

- Yarn defects such every bit thick & sparse places

- Darts & Stains

- Verify cutting patterns

- Cut components measurements

- Cutting shapes

- Fabric defects

- Rib, Collars & Cuffs matching

- Stitching defects

- Sewing threads matching

- Dirt & Stains

- Measurements

- Labels

- Trims & Accessories

Many of the of import parameters of Pre-productions, during productions & Final inspection parameters. This is to ensure that incorrect or major defective garments are non packed.

FINAL INSPECTION

A. PACKING & ASSORTMENT

- Wrong Model

- Wrong Quantity

- Missing labels & tags

- Wrong Size & Colour assortment

- Wrong Folding

- Wrong Shade

- Uneven dyeing

- Holes

- Knitting stripes

- Thick & Thin places

- Dirt & Stains

- Oil stains

- Sinker line of piece of job

- Poor softness

- Higher Shrinkage

- Crease Marks

- Open seam

- Puckering

- Needle holes & marks

- Unbalanced sleeve border

- Unbalanced placket

- Insecure shoulder sew together

- Incorrect side shape

- Bottom hem bowing

- Uneven cervix shape

- Cross labels

- Broken & Missing sew together

- In secured buttons

- Untrimmed threads & fabrics

- Poor Ironing

- Double sew together

- Shade variation inside the garment parts

- Shade variation betwixt the garments

- Defective printing

- Defective embroidery

- Defective buttons

Compare the garment measurements against the Customers Measurement Charts. Following are the to a greater extent than or less of the of import garments measuring aspects to survive considered.

- Garment length

- Body width

- Shoulder length

- Arm hole

- Arm opening

- Sleeve length

- Placket length

- Placket Width

- Neck width

- Neck opening

- Hemming width

- Rib or Collar width

H5N1 for sure proportion of defective volition e'er occur inwards whatsoever manufacturing process. If the percent does non laissez passer on a for sure limit, it volition survive economical to permit the defective to larn through instead of screening the entire lot. This boundary is called the “Acceptable Quality Level” (AQL)

Considering the practical & economical aspects, Sampling Techniques are adopted to bring or turn down a Lot on the Blue Planet of the Samples drawn at Random from the lot. It has been found in addition to accepted that a scientifically designed sampling & inspection programme protects a Manufacturer too every bit the Buyer economically.

American Military standards known every bit MIL-STD-105A to 105E is accepted worldwide for sampling sizes. It has the next sample size levels. Normally for Garment Industry 105D or 105E are followed.

ECOLOGICAL PARAMETERS

Now all the Customers are bespeak for Ecological Parameters. Now European Buyers are stressing this. Following are master copy Ecological Parameters to survive considered.

- PH hit

- Formaldehyde levels

- Extractable heavy metals

- Chlorinated phenols (PCP, Te CP)

- Forbidden Amines of MAK III A1& A2 categories

- Pesticides

- Chlorinated Organic carriers

- Biocide finishes

- Flame retardant finishes

- Colour fastness to Water

- Colour fastness to acid & alkali perspiration

- Colour fastness to saliva

- Colour fastness to Wet & dry out rubbing

- Emission of volatile chemicals

- Other specific parameters every bit required past times the customers

Quality Control System inwards Apparel Industry plays an vital locomote in addition to volition construct upward skillful human relationship betwixt Buyer in addition to manufacturer. Now a days customers prefer to purchase the goods to satisfy their requirements. To construct upward skillful human relationship betwixt manufacturer in addition to customer, character command organisation is e'er helping every bit a wonderful dyad betwixt them.