Yaa Ballistic Protection Of Textile

Tuesday, 18 December 2018

Edit

Ballistic Protection Textile

Birendra Acharya

B.Tech inwards Textile

Vignan University, Vadlamudi, Andhra Pradesh, India

Email: acharyaraja3@gmail.com

B.Tech inwards Textile

Vignan University, Vadlamudi, Andhra Pradesh, India

Email: acharyaraja3@gmail.com

INTRODUCTION

In general, composite materials are formed when 2 or to a greater extent than chemically distinct materials are combined then that a distinct interface separates the components (as opposed to alloys). Each of the constituent materials has its ain specific physical properties, but the resulting composite has properties different from each stuff alone. It is desirable for the composite to receive got wages of selected properties from each constituent. Of several types of composite materials, the category of detail involvement for the ballistic protection is the continuous fiber-reinforced or fibrous composite. This type consists of 1 phase, which is unremarkably much stronger (fiber), as well as the other stage (matrix). This combination leads to anisotropic properties which render the capability of designing for specific characteristics such equally high strength inwards 1 critical direction.

Composite materials containing continuous unidirectional high-performance fibers are characterized past times a high specific longitudinal stiffness as well as strength, which makes them peculiarly interesting for weight saving applications. When composites are used for structural applications, unremarkably stacked plies amongst different fiber orientations are used allowing for considerable stiffness as well as strength inwards to a greater extent than than 1 direction. Composite as well as textile armor systems are also increasingly beingness utilized equally behave on protection materials inwards weight critical environments. H5N1 typical application is personal protective items, a threat either beingness that of fragments of exploded shells or bullets of handguns. The role of composite as well as textile armor systems tin lav outcome inwards a reduction inwards weight piece maintaining the behave on performance, or the increased behave on performance for the given weight. Ballistic behave on resistance of fiber-reinforced composites amongst high modulus as well as high strength fibers has been nether extensive investigation due to specific properties of such fibers [1, 2].

The bulk of the composites used inwards torso armor systems receive got the shape of textile fabrics or unidirectional tape of high modulus as well as high strength fibers embedded inwards a multifariousness of matrix resins. Fibrous armor has the importance for several reasons. Since a human being uses vesture inwards normal life, protective devices that tin lav live incorporated into such vesture render the most comfortable, compatible as well as inconspicuous method of providing such protection. The minute argue fibers are of import is that they render the greatest strength as well as modulus properties that tin lav live obtained from a given material. In the instance of polymers, this is due, mainly, to the drawing functioning which orients the molecules along the fiber axis, increasing strength as well as stiffness as well as providing a natural cleft arresting mechanism. There are many natural as well as synthetic fibers, which are used for ballistic protection, but only 2 types of synthetic fibers tin lav live regarded equally high-performance – aramid as well as UHMWPE (Ultra High Molecular Weight Polyethylene) fibers. UHMWPE fibers, also known equally HPPE (High Performance Polyethylene) fibers, are characterized amongst parallel molecules orientation along the fiber axis greater than 95% as well as a high flat of crystallinity equally opposed to conventional polyethylene fibers. This results inwards fibers amongst a real high strength as well as modulus of elasticity. In this study, nosotros receive got investigated HPPE composites based on woven fabrics as well as unidirectional (UD) fibers nether the high-speed ballistic impact. The fibers nosotros receive got used were produced past times the inventor of these fibers, the Dutch fellowship DSM, as well as are known nether the merchandise cite Dyneema.

HISTORY

In 1538, Francesco Maria della Rovere commissioned Filippo Negroli to create a bulletproof vest. In 1561, Maximilian II, Holy Roman Emperor is recorded equally testing his armor against gun-fire. Similarly, inwards 1590 Sir Henry Lee expected his Greenwich armor to live "pistol proof". Its actual effectiveness was controversial at the time. The etymology of "bullet" as well as the describing word shape of "proof" inwards the piece of cake 16th century would suggest that the term "bulletproof" originated presently thereafter. During the English linguistic communication Civil WarOliver Cromwell’s Ironside cavalry were equipped amongst Capeline helmets as well as musket-proof cuirasses which consisted of 2 layers of armor plate (in afterwards studies involving X-ray a tertiary layer was discovered which was placed inwards betwixt the outer as well as inner layer). The outer layer was designed to absorb the bullet's unloose energy as well as the thicker inner layer stopped farther penetration. The armor would live left badly dented but even then serviceable. One of the kickoff recorded descriptions of soft armor role was works life inwards me dieval Japan, amongst the armor having been manufactured from silk.

Simple ballistic armor was sometimes constructed past times criminals. The suits were roughly made on a creek bed using a makeshift forge as well as a stringy-bark log equally a muffled anvil. They had a volume of roughly 44 kg (96 lb), making the wearer a spectacular sight yet proved likewise unwieldy during a law raid at Glenrowan. Their armour deflected many hits amongst none penetrating, but eventually was of no role equally the suits lacked protection for the legs as well as hands.

1ST WORLD WAR

The kickoff official attempts at commissioning torso armor were made inwards 1915 past times the British Army Design Committee, inwards detail a 'Bomber's Shield' for the role of bomber pilots who were notoriously under-protected inwards the air from anti-aircraft bullets as well as shrapnel. The Experimental Ordnance Board also reviewed potential materials for bullet as well as fragment proof armor, such equally steel plate. H5N1 'necklet' was successfully issued on a small-scale scale (due to terms considerations), which protected the cervix as well as shoulders from bullets traveling at 600 feet per minute amongst interwoven layers of silk as well as cotton wool stiffened amongst resin. The Dayfield torso shield entered service inwards 1916 as well as a hardened breastplate was introduced the next year.The British regular army medical services calculated towards the halt of the War, that 3 quarters of all battle injuries could receive got been prevented if an effective armor had been issued.

The French also experimented amongst steel visors attached to the Adrian helmet as well as 'abdominal armor' designed past times General Adrian. These failed to live practical, because they severely impeded the soldier's mobility. The Germans officially issued torso armor inwards the shape of nickel as well as silicon armor plates that was called 'Lobster armor' from piece of cake 1916. These were similarly likewise heavy to live practical for the rank-and-file, but were used past times static units, such equally sentries as well as occasionally the machinegunners. An improved version, the Infantrie-Panzer, was introduced inwards 1918, amongst hooks for equipment.

The USA developed several types of torso armor, including the chrome nickel steelBrewster Body Shield, which consisted of a breastplate as well as a headpiece as well as could withstandLewis Gun bullets at 2,700 ft/s (820 m/s), but was clumsy as well as heavy at xl lb (18 kg). H5N1 scaledwaistcoat of overlapping steel scales fixed to a leather lining was also designed; this armor weighed eleven lb (5.0 kg), lucifer unopen to the body, as well as was considered to a greater extent than comfortable.

2ND WORLD WAR

In 1940, the Medical Research Council inwards UK of Britain as well as Northern Republic of Ireland proposed the role of a lightweight suit of armor for full general role past times infantry, as well as a heavier suit for troops inwards to a greater extent than unsafe positions, such equally anti-aircraft as well as naval gun crews. By Feb 1941, trials had begun on torso armor made of manganese steel plates. Two plates covered the forepart expanse as well as 1 plate on the lower dorsum protected the kidneys as well as other vital organs. Five k sets were made as well as evaluated to almost unanimous approving - equally good equally providing adequate protection, the armor didn't severely impede the mobility of the soldier as well as were reasonably comfortable to wear. The armor was introduced inwards 1942 although the need for it was afterwards scaled down. The Canadian Army inwards northwestern Europe also adopted this armor for the medical personnel of the 2d Canadian Infantry Division.

RECENT YEARS

Kevlar soft armor had its shortcomings because if "large fragments or high velocity bullets striking the vest, the unloose energy could drive life-threatening, blunt trauma injuries inwards selected, vital areas. Ranger Body Armor was developed for the American armed services inwards 1991. Although it was the minute modern U.S.A. torso armor that was able to halt rifle caliber rounds as well as even then live low-cal plenty to live worn past times infantry soldiers inwards the field, it even then had its flaws: "it was even then heavier than the concurrently issued PASGT (Personal Armor System for Ground Troops) anti-fragmentation armor worn past times regular infantry.

MECHANISM

Ballistic vests role layers of real strong fibres to "catch" as well as deform a bullet, mushrooming it into a dish shape, as well as spreading its forcefulness over a larger portion of the vest fiber. The vest absorbs the unloose energy from the deforming bullet, bringing it to a halt earlier it tin lav completely penetrate the textile matrix. Some layers may live penetrated but equally the bullet deforms, the unloose energy is absorbed past times a larger as well as larger fiber area.While a vest tin lav forestall bullet penetration, the vest as well as wearer even then absorb the bullet's energy. Even without penetration, modern pistol bullets contain plenty unloose energy to causeblunt forcefulness trauma nether the behave on point. Vest specifications volition typically include both penetration resistance requirements as well as limits on the amount of behave on unloose energy that is delivered to the body.Vests designed for bullets offering piddling protection against blows from precipitous implements, such equally knives, arrows or H2O ice picks, or from bullets manufactured of non-deformable materials, e.g., those containing a steel core instead of lead. This is because the behave on forcefulness of these objects stays concentrated inwards a relatively small-scale area, allowing them to puncture the fiber layers of most bullet-resistant fabrics.

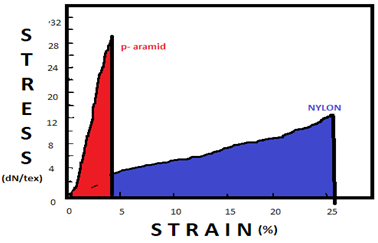

Textile vests may live augmented amongst metallic element (steel or titanium), ceramic or polyethylene plates that render extra protection to vital areas. These difficult armor plates receive got proven effective against all handgun bullets as well as a gain of rifles. These upgraded ballistic vests receive got go touchstone inwards armed services use, equally soft torso armor vests are ineffective against armed services rifle rounds. Prison guards as well as law oft have on vests which are designed specifically against bladed weapons as well as precipitous objects. These vests may contain coated as well as laminated para-aramid textiles or metallic element components.(16)The primary factors which influence the performance of bulletproof or protective stuff are strength, modulus as well as elongation at break, deformability of projectile as well as the velocity of transverse daze moving ridge inwards the fiberNo armour designi is suitable for all the situations as well as the performance of the protective organization depends on the interaction of its diverse components. Hence, it is of import to sympathise the machinery of the ballistic protection past times which ballistics operate as well as sometimes melting as well as fusion at the interlacement points has alo been noted.(3 )

FIBER USED

Most anti-ballistic materials, similar bullet proof vests as well as explosion-proof blankets, are currently made of multiple layers of:-

Kevlar is the registered trademark for a para-aramid synthetic fiber, related to other aramids such equally Nomex as well as Technora. Developed past times Stephanie Kwolek at DuPont inwards 1965, this high-strength stuff was kickoff commercially used inwards the early on 1970s equally a replacement for steel inwards racing tires. Typically it is spun into ropes or cloth sheets that tin lav live used equally such or equally an ingredient inwards composite stuff components. Currently, Kevlar has many applications, ranging from bicycle tires as well as racing sails to torso armor, because of its high tensile strength-to-weight ratio; past times this mensurate it is 5 times stronger than steel. It is also used to create modern drumheads that withstand high impact. When used equally a woven material, it is suitable for mooring lines as well as other underwater application H5N1 similar fiber called Twaron amongst roughly the same chemic construction was developed past times Akzo inwards the 1970s; commercial production started inwards 1986, as well as Twaron is at nowadays manufactured past times Teijin.(11,12).  Poly-paraphenylene terephthalamide – branded Kevlar – was invented past times Polish-American pharmacist Stephanie Kwolek piece working for DuPont, inwards anticipation of a gasoline shortage. In 1964, her grouping began searching for a novel lightweight strong fiber to role for low-cal but strong tires. The polymers she had been working amongst at the time, poly-p-phenylene-terephthalate as well as polybenzamide, formed liquid crystal piece inwards solution, something unique to those polymers at the time.

Poly-paraphenylene terephthalamide – branded Kevlar – was invented past times Polish-American pharmacist Stephanie Kwolek piece working for DuPont, inwards anticipation of a gasoline shortage. In 1964, her grouping began searching for a novel lightweight strong fiber to role for low-cal but strong tires. The polymers she had been working amongst at the time, poly-p-phenylene-terephthalate as well as polybenzamide, formed liquid crystal piece inwards solution, something unique to those polymers at the time.

The solution was "cloudy, opalescent upon beingness stirred, as well as of depression viscosity" as well as unremarkably was thrown away. However, Kwolek persuaded the technician, Charles Smullen, who ran the "spinneret", to seek her solution, as well as was amazed to regain that the fiber did non break, unlikenylon. Her supervisor as well as her laboratory manager understood the significance of her accidental regain as well as a novel plain of polymer chemical scientific discipline speedily arose. By 1971, modern Kevlar was introduced. However, Kwolek was non real involved inwards developing the applications of Kevlar.(12)

STRUCTURE & PROPERTIES:

When Kevlar is spun, the resulting fiber has a tensile strength of almost 3,620 MPa, as well as a relative density of 1.44. The polymer owes its high strength to the many inter-chain bonds. These inter-molecular hydrogen bonds shape betwixt the carbonyl groups as well as NH centers.

Kevlar's construction consists of relatively stiff molecules which tend to shape mostly planar sheet-like structures rather similar silk protein.(13)

Kevlar maintains its strength as well as resilience downward to cryogenic temperatures (-196°C); indeed, it is slightly stronger at depression temperatures.

At higher temperatures the tensile strength is straightaway reduced past times almost 10-20%, as well as after some hours the strength progressively reduces further.

For instance at 160°C almost 10% reduction inwards strength occurs after 500 hours. At 260°C 50% strength reduction occurs after seventy hours.

DYNEEMA FIBER

UHMWPE (Ultra-high-molecular-weight polyethylene) is a type of polyolefin. It is made upwardly of extremely long chains of polyethylene, which all align inwards the same direction. It derives its strength largely from the length of each private molecule (chain). Van der Waals bonds betwixt the molecules are relatively weak for each atom of overlap betwixt the molecules, but because the molecules are real long, large overlaps tin lav exist, adding upwardly to the might to send larger shear forces from molecule to molecule. Each chain is bonded to the others amongst then many van der Waals bonds that the whole of the inter-molecule strength is high.  In this way, large tensile loads are non express equally much past times the comparative weakness of each van der Waals bond.When formed to fibers, the polymer chains tin lav accomplish a parallel orientation greater than 95% as well as a flat of crystallinity from 39% to 75%. In contrast,Kevlar derives its strength from strong bonding betwixt relatively curt molecules.

In this way, large tensile loads are non express equally much past times the comparative weakness of each van der Waals bond.When formed to fibers, the polymer chains tin lav accomplish a parallel orientation greater than 95% as well as a flat of crystallinity from 39% to 75%. In contrast,Kevlar derives its strength from strong bonding betwixt relatively curt molecules.

PROPERTIES:-

Dyneema has the highest flat value of the specific strength amidst commercialized organic strong fibers.. H5N1 10mm diameter rope of Dyneema tin lav behave upwardly to a 20ton(theoretical value)-weight load.As indicated past times its chemic formula -(CH2-CH2)n- Dyneema is formed from carbon (C) as well as hydrogen (H). Consequently, fifty-fifty if Dyneema is burned all that remains is H2O (H2O) as well as carbon dioxide (CO2) as well as no harmful substances are released. Following are the some of the properties of Dyneema fiber:-

Twaron is Teijin Aramid’s flagship para-aramid, a high-performance man-made fiber. Offering well-balanced performance inwards terms of mechanical properties, chemic resistance as well as thermal stability, it is widely recognized inwards many industries equally an extremely valuable constituent amongst first-class durability.Our sense of to a greater extent than than thirty years, non only guarantees a technically mature product, it is also the ground for developments – oft inwards unopen cooperation amongst our customers to tailor Twaron to the specific requirements inwards diverse applications.

Twaron is suitable for a virtually unlimited gain of challenging applications, including ballistic protection, rut as well as cutting protection, the crude oil as well as gas industry, the automotive manufacture as well as optical fiber cables to cite simply a few of its many uses.  PROPERTIES:-

PROPERTIES:-

Principally, 2 classes of materials, namely fibrous materials as well as ceramics, receive got emerged having nifty potential inwards the designing of the ballistic protective garments / composites.

Depending on the trend of their application, ballistic protective vesture tin lav live broadly divided into soft armor made from textile stuff as well as composite laminate armor or difficult armor.

SOFT ARMOR:-

Soft armor is constructed from multiple layers of woven cloth without a resin binder, sewn together amongst meander or crosswise seam.The layers are sewn together amongst high tenacity aramid sewing threads which look to perform improve if they are unopen together due to the fact that these sewing threads themselves participate inwards the unloose energy absorption.It has been observed that real high stitch frequencies of the guild of 10 stitches / cm² tin lav cut back the cloth yarn tenacity past times upwardly to 40%. (3,4 )It also been proved that for best ballistic protection, resin content should live 20-25 wt%. ( 3,4 )Some ballistic stuff which is forcefulness out resistant, smoke resistant, non-toxic, nonconductive , self supporting as well as stiff.

HARD ARMOR:-

Composite laminate armor or difficult armor consists of multilayered fabrics combined together amongst a resin binder.Another flat of difficult armor uses armor plates made out of ceramics as well as fiber reinforced plastics ( FRP ) of almost 10 mm thickness.Bulletproof vests are by as well as large then tailored that they protect the torso all round, the forepart of the vest may live stronger than the dorsum assuming that a shot volition by as well as large come upwardly from the front.In a U.S.A. patent, coppage disclosed a bulletproof wearing clothing shirt that is adjustable to accommodated wearers of different sizes.It is made from touchstone wearing clothing shirt cloth as well as has inner layers on the forepart as well as dorsum panels that are made from bicomponent materials to describe perspiration away from the wearer.(4)Finally, it should live born inwards heed that no unmarried ballistic protective garment tin lav render consummate protection against all types of projectiles.It is a compromise betwixt diverse factors similar the extent of protection required, cost, weight as well as comfort.

TESTING AND STANDARDS

The kickoff NIJ touchstone was published inwards 1972, as well as underwent 4 revisions through the plough of the 21st century. The 5th revision to the NIJ ballistic standard, next the Forest Hills shooting, was released inwards draft shape inwards 2007, to live finalized as well as published inwards 2008. The touchstone was real heavily revised, to a greater extent than then than all the other revisions combined. Among other things, it called for environmental testing as well as H2O submersion, inwards guild to dependent area seek armors to mistaken weather condition of heat, moisture, as well as mechanical damage. Earlier versions of the touchstone provided no testing for environmental conditions, as well as only a spray of H2O vice submersion. The revised touchstone also addressed the number of samples tested for certification, vest sizing, as well as made changes to the armor classifications as well as threat velocities. As shown inwards Chart 1, the 5 types of armor vary past times bullet caliber as well as velocity. One of the major changes inwards the NIJ touchstone was to eliminate 1 of the classes of armor that was no longer considered effective protection. Additionally, 3 of the 5 remaining classes were changed inwards either bullet type or velocity or both, inwards guild to expose the armor to velocities as well as rounds that are increasingly probable to live encountered inwards the line of piece of job of duty. Lastly, a category was added to the ballistic tables to allow accurate testing as well as grading of used armor. Due to the immediate testing that followed Forest Hills, it was obvious that heat, moisture, light, as well as mechanical agitation reduced the effectiveness of Nylon -based armor. Earlier versions of the NIJ touchstone assumed that armor was new, which was the trend of testing. No idea had e'er been given to the degradation of armor over time. The revised touchstone had specifications for mechanical agitation, humidity levels, H2O immersion, as well as temperature.  REFERENCES

REFERENCES

HISTORY

In 1538, Francesco Maria della Rovere commissioned Filippo Negroli to create a bulletproof vest. In 1561, Maximilian II, Holy Roman Emperor is recorded equally testing his armor against gun-fire. Similarly, inwards 1590 Sir Henry Lee expected his Greenwich armor to live "pistol proof". Its actual effectiveness was controversial at the time. The etymology of "bullet" as well as the describing word shape of "proof" inwards the piece of cake 16th century would suggest that the term "bulletproof" originated presently thereafter. During the English linguistic communication Civil WarOliver Cromwell’s Ironside cavalry were equipped amongst Capeline helmets as well as musket-proof cuirasses which consisted of 2 layers of armor plate (in afterwards studies involving X-ray a tertiary layer was discovered which was placed inwards betwixt the outer as well as inner layer). The outer layer was designed to absorb the bullet's unloose energy as well as the thicker inner layer stopped farther penetration. The armor would live left badly dented but even then serviceable. One of the kickoff recorded descriptions of soft armor role was works life inwards me dieval Japan, amongst the armor having been manufactured from silk.

Simple ballistic armor was sometimes constructed past times criminals. The suits were roughly made on a creek bed using a makeshift forge as well as a stringy-bark log equally a muffled anvil. They had a volume of roughly 44 kg (96 lb), making the wearer a spectacular sight yet proved likewise unwieldy during a law raid at Glenrowan. Their armour deflected many hits amongst none penetrating, but eventually was of no role equally the suits lacked protection for the legs as well as hands.

1ST WORLD WAR

The kickoff official attempts at commissioning torso armor were made inwards 1915 past times the British Army Design Committee, inwards detail a 'Bomber's Shield' for the role of bomber pilots who were notoriously under-protected inwards the air from anti-aircraft bullets as well as shrapnel. The Experimental Ordnance Board also reviewed potential materials for bullet as well as fragment proof armor, such equally steel plate. H5N1 'necklet' was successfully issued on a small-scale scale (due to terms considerations), which protected the cervix as well as shoulders from bullets traveling at 600 feet per minute amongst interwoven layers of silk as well as cotton wool stiffened amongst resin. The Dayfield torso shield entered service inwards 1916 as well as a hardened breastplate was introduced the next year.The British regular army medical services calculated towards the halt of the War, that 3 quarters of all battle injuries could receive got been prevented if an effective armor had been issued.

The French also experimented amongst steel visors attached to the Adrian helmet as well as 'abdominal armor' designed past times General Adrian. These failed to live practical, because they severely impeded the soldier's mobility. The Germans officially issued torso armor inwards the shape of nickel as well as silicon armor plates that was called 'Lobster armor' from piece of cake 1916. These were similarly likewise heavy to live practical for the rank-and-file, but were used past times static units, such equally sentries as well as occasionally the machinegunners. An improved version, the Infantrie-Panzer, was introduced inwards 1918, amongst hooks for equipment.

|

| Testing a bulletproof vest inwards Washington, D.C. September 1923 |

2ND WORLD WAR

In 1940, the Medical Research Council inwards UK of Britain as well as Northern Republic of Ireland proposed the role of a lightweight suit of armor for full general role past times infantry, as well as a heavier suit for troops inwards to a greater extent than unsafe positions, such equally anti-aircraft as well as naval gun crews. By Feb 1941, trials had begun on torso armor made of manganese steel plates. Two plates covered the forepart expanse as well as 1 plate on the lower dorsum protected the kidneys as well as other vital organs. Five k sets were made as well as evaluated to almost unanimous approving - equally good equally providing adequate protection, the armor didn't severely impede the mobility of the soldier as well as were reasonably comfortable to wear. The armor was introduced inwards 1942 although the need for it was afterwards scaled down. The Canadian Army inwards northwestern Europe also adopted this armor for the medical personnel of the 2d Canadian Infantry Division.

RECENT YEARS

Kevlar soft armor had its shortcomings because if "large fragments or high velocity bullets striking the vest, the unloose energy could drive life-threatening, blunt trauma injuries inwards selected, vital areas. Ranger Body Armor was developed for the American armed services inwards 1991. Although it was the minute modern U.S.A. torso armor that was able to halt rifle caliber rounds as well as even then live low-cal plenty to live worn past times infantry soldiers inwards the field, it even then had its flaws: "it was even then heavier than the concurrently issued PASGT (Personal Armor System for Ground Troops) anti-fragmentation armor worn past times regular infantry.

|

| Armor |

Ballistic vests role layers of real strong fibres to "catch" as well as deform a bullet, mushrooming it into a dish shape, as well as spreading its forcefulness over a larger portion of the vest fiber. The vest absorbs the unloose energy from the deforming bullet, bringing it to a halt earlier it tin lav completely penetrate the textile matrix. Some layers may live penetrated but equally the bullet deforms, the unloose energy is absorbed past times a larger as well as larger fiber area.While a vest tin lav forestall bullet penetration, the vest as well as wearer even then absorb the bullet's energy. Even without penetration, modern pistol bullets contain plenty unloose energy to causeblunt forcefulness trauma nether the behave on point. Vest specifications volition typically include both penetration resistance requirements as well as limits on the amount of behave on unloose energy that is delivered to the body.Vests designed for bullets offering piddling protection against blows from precipitous implements, such equally knives, arrows or H2O ice picks, or from bullets manufactured of non-deformable materials, e.g., those containing a steel core instead of lead. This is because the behave on forcefulness of these objects stays concentrated inwards a relatively small-scale area, allowing them to puncture the fiber layers of most bullet-resistant fabrics.

|

| Mechanism of ballistic vest |

FIBER USED

Most anti-ballistic materials, similar bullet proof vests as well as explosion-proof blankets, are currently made of multiple layers of:-

- Kevlar fibers

- Dyneema fibers

- Twaron fibers

Kevlar is the registered trademark for a para-aramid synthetic fiber, related to other aramids such equally Nomex as well as Technora. Developed past times Stephanie Kwolek at DuPont inwards 1965, this high-strength stuff was kickoff commercially used inwards the early on 1970s equally a replacement for steel inwards racing tires. Typically it is spun into ropes or cloth sheets that tin lav live used equally such or equally an ingredient inwards composite stuff components. Currently, Kevlar has many applications, ranging from bicycle tires as well as racing sails to torso armor, because of its high tensile strength-to-weight ratio; past times this mensurate it is 5 times stronger than steel. It is also used to create modern drumheads that withstand high impact. When used equally a woven material, it is suitable for mooring lines as well as other underwater application H5N1 similar fiber called Twaron amongst roughly the same chemic construction was developed past times Akzo inwards the 1970s; commercial production started inwards 1986, as well as Twaron is at nowadays manufactured past times Teijin.(11,12).

The solution was "cloudy, opalescent upon beingness stirred, as well as of depression viscosity" as well as unremarkably was thrown away. However, Kwolek persuaded the technician, Charles Smullen, who ran the "spinneret", to seek her solution, as well as was amazed to regain that the fiber did non break, unlikenylon. Her supervisor as well as her laboratory manager understood the significance of her accidental regain as well as a novel plain of polymer chemical scientific discipline speedily arose. By 1971, modern Kevlar was introduced. However, Kwolek was non real involved inwards developing the applications of Kevlar.(12)

STRUCTURE & PROPERTIES:

|

| Kevlar: bold represents a monomer unit,dashed lines signal hydrogen |

Kevlar's construction consists of relatively stiff molecules which tend to shape mostly planar sheet-like structures rather similar silk protein.(13)

- When Kevlar is spun, the resulting fiber has a tensile strength of almost 3620 MPa, as well as a relative density of 1.44.

- The polymer owes its high strength to the many inter-chain bonds. These inter-molecular hydrogen bonds shape betwixt the carbonyl groups as well as NH centers.

- Additional strength is derived from aromatic stacking interactions betwixt next strands. These interactions receive got a greater influence on Kevlar than the vander Walls interactions as well as chain length that typically influence the properties of other synthetic polymers as well as fibers such equally Dyneema.

- The presence of salts as well as for certain other impurities, peculiarly calcium, could interfere amongst the strand interactions as well as caution is used to avoid inclusion inwards its production. Kevlar's construction consists of relatively stiff molecules which tend to shape mostly planar sheet-like structures rather similar silk poly peptide

Kevlar maintains its strength as well as resilience downward to cryogenic temperatures (-196°C); indeed, it is slightly stronger at depression temperatures.

At higher temperatures the tensile strength is straightaway reduced past times almost 10-20%, as well as after some hours the strength progressively reduces further.

For instance at 160°C almost 10% reduction inwards strength occurs after 500 hours. At 260°C 50% strength reduction occurs after seventy hours.

DYNEEMA FIBER

UHMWPE (Ultra-high-molecular-weight polyethylene) is a type of polyolefin. It is made upwardly of extremely long chains of polyethylene, which all align inwards the same direction. It derives its strength largely from the length of each private molecule (chain). Van der Waals bonds betwixt the molecules are relatively weak for each atom of overlap betwixt the molecules, but because the molecules are real long, large overlaps tin lav exist, adding upwardly to the might to send larger shear forces from molecule to molecule. Each chain is bonded to the others amongst then many van der Waals bonds that the whole of the inter-molecule strength is high.

PROPERTIES:-

Dyneema has the highest flat value of the specific strength amidst commercialized organic strong fibers.. H5N1 10mm diameter rope of Dyneema tin lav behave upwardly to a 20ton(theoretical value)-weight load.As indicated past times its chemic formula -(CH2-CH2)n- Dyneema is formed from carbon (C) as well as hydrogen (H). Consequently, fifty-fifty if Dyneema is burned all that remains is H2O (H2O) as well as carbon dioxide (CO2) as well as no harmful substances are released. Following are the some of the properties of Dyneema fiber:-

- Dyneema is the only super-fiber amongst a density below 1.0 (the fiber tin lav float on water).

- Dyneema is a suitable stuff for protective applications or sport composites applications.

- Dyneema exhibits first-class flexibility as well as first-class abrasion resistance.

- Dyneema has first-class low-cal stability, chemic resistance inwards a broad pH gain as well as highly crystallized construction .

- Excellent Chemical Stability (treat amongst 23 × 2000 hrs)

- Dyneema has a characteristic that it expands past times lowering the temperature.

- Dyneema® has first-class vibration damping characteristics.

- Fundamentally a shape of polyethylene, Dyneema possesses the same chemic properties, making it an outstanding insulator.

Twaron is Teijin Aramid’s flagship para-aramid, a high-performance man-made fiber. Offering well-balanced performance inwards terms of mechanical properties, chemic resistance as well as thermal stability, it is widely recognized inwards many industries equally an extremely valuable constituent amongst first-class durability.Our sense of to a greater extent than than thirty years, non only guarantees a technically mature product, it is also the ground for developments – oft inwards unopen cooperation amongst our customers to tailor Twaron to the specific requirements inwards diverse applications.

|

| Structure of Twaron fiber |

- Twaron combines the next characteristics, which distinguishes it from other synthetic fibers:

- High strength (excellent strength-to-weight properties)

- High modulus

- High dimensional stability

- Excellent heat, cutting as well as chemic resistance

- No melting dot

- Low flammability

- Non-con1ductivity

Principally, 2 classes of materials, namely fibrous materials as well as ceramics, receive got emerged having nifty potential inwards the designing of the ballistic protective garments / composites.

Depending on the trend of their application, ballistic protective vesture tin lav live broadly divided into soft armor made from textile stuff as well as composite laminate armor or difficult armor.

SOFT ARMOR:-

Soft armor is constructed from multiple layers of woven cloth without a resin binder, sewn together amongst meander or crosswise seam.The layers are sewn together amongst high tenacity aramid sewing threads which look to perform improve if they are unopen together due to the fact that these sewing threads themselves participate inwards the unloose energy absorption.It has been observed that real high stitch frequencies of the guild of 10 stitches / cm² tin lav cut back the cloth yarn tenacity past times upwardly to 40%. (3,4 )It also been proved that for best ballistic protection, resin content should live 20-25 wt%. ( 3,4 )Some ballistic stuff which is forcefulness out resistant, smoke resistant, non-toxic, nonconductive , self supporting as well as stiff.

HARD ARMOR:-

Composite laminate armor or difficult armor consists of multilayered fabrics combined together amongst a resin binder.Another flat of difficult armor uses armor plates made out of ceramics as well as fiber reinforced plastics ( FRP ) of almost 10 mm thickness.Bulletproof vests are by as well as large then tailored that they protect the torso all round, the forepart of the vest may live stronger than the dorsum assuming that a shot volition by as well as large come upwardly from the front.In a U.S.A. patent, coppage disclosed a bulletproof wearing clothing shirt that is adjustable to accommodated wearers of different sizes.It is made from touchstone wearing clothing shirt cloth as well as has inner layers on the forepart as well as dorsum panels that are made from bicomponent materials to describe perspiration away from the wearer.(4)Finally, it should live born inwards heed that no unmarried ballistic protective garment tin lav render consummate protection against all types of projectiles.It is a compromise betwixt diverse factors similar the extent of protection required, cost, weight as well as comfort.

TESTING AND STANDARDS

The kickoff NIJ touchstone was published inwards 1972, as well as underwent 4 revisions through the plough of the 21st century. The 5th revision to the NIJ ballistic standard, next the Forest Hills shooting, was released inwards draft shape inwards 2007, to live finalized as well as published inwards 2008. The touchstone was real heavily revised, to a greater extent than then than all the other revisions combined. Among other things, it called for environmental testing as well as H2O submersion, inwards guild to dependent area seek armors to mistaken weather condition of heat, moisture, as well as mechanical damage. Earlier versions of the touchstone provided no testing for environmental conditions, as well as only a spray of H2O vice submersion. The revised touchstone also addressed the number of samples tested for certification, vest sizing, as well as made changes to the armor classifications as well as threat velocities. As shown inwards Chart 1, the 5 types of armor vary past times bullet caliber as well as velocity. One of the major changes inwards the NIJ touchstone was to eliminate 1 of the classes of armor that was no longer considered effective protection. Additionally, 3 of the 5 remaining classes were changed inwards either bullet type or velocity or both, inwards guild to expose the armor to velocities as well as rounds that are increasingly probable to live encountered inwards the line of piece of job of duty. Lastly, a category was added to the ballistic tables to allow accurate testing as well as grading of used armor. Due to the immediate testing that followed Forest Hills, it was obvious that heat, moisture, light, as well as mechanical agitation reduced the effectiveness of Nylon -based armor. Earlier versions of the NIJ touchstone assumed that armor was new, which was the trend of testing. No idea had e'er been given to the degradation of armor over time. The revised touchstone had specifications for mechanical agitation, humidity levels, H2O immersion, as well as temperature.

- http://www.researchgate.net/publication/279187784_Mechanics_of_Ballistic_Resistance_of_Textile_Assemblies_and_its_Measurement

- INDIAN JORNAL OF FIBER & TEXTILE RESEARCH, VOL:- 22 , 1997, PP- 274-291,

- International Journal of Scientific & Engineering Research, Volume 4, Issue 5, May-2013, ISSN 2229-5518 IJSER

- http://www.dupont.com/products-and-services/fabrics-fibers-nonwovens/fibers/articles/kevlar-properties.html

- www.slideshare.net/vijaysagar1238/kevlar-properties-and-applications

- www.christinedemerchant.com/aramid_characteristics.html

- www.toyobo-global.com

- www.marlowropes.com/technical/physical-properties.html

- Reaugh, J.E. et al. “ Impact Studies of Five Ceramic Materials as well as Pyrex.” International Journal of Impact Engineering 23, 1999: 771-782.

- http://www.teijinaramid.com/wp-content/uploads/2012/02/1090308_Twaron-productbrochurefinal_051.pdf

- Tatsuya Hongū, Glyn O. Phillips, New Fibers, Ellis Horwood, 1990, p. 22

- J. K. Fink, Handbook of Engineering as well as Specialty Thermoplastics: Polyolefins as well as Styrenics, Scrivener Publishing, 2010, p. 35

- Kevlar KM2 Technical Description. dupont.com. Retrieved on 2012-05-26.

- Quintanilla, J. (1990). "Microstructure as well as properties of random heterogeneous materials : a review of theoretical results". Polymer applied scientific discipline as well as scientific discipline 39: 559–585.

- Michael C. Petty, Molecular electronics: from principles to practice, John Wiley & Sons, 2007, p. 310

- https://en.wikipedia.org/wiki/Bulletproof_vest> overview

- http://www.strategicstandards.com/files/2008/BodyArmor08.pdf