Now You Know Innovation in Spinning Technologies for Denim Wear

Friday, 1 June 2018

Edit

Innovation in Spinning Technologies for Denim Wear

Amirsuhel Aslam Desai Danwade

D.K.T.E’s Textile and Engineering Institute,

D.K.T.E’s Textile and Engineering Institute,

Introduction:-

The word denim was coined from the ancient city of France called serge de Nemis. Denim is a sturdy fabric usually made up from 3/1 twill with indigo dyed warp faced and white filling yarns in the weft of coarser counts. It uses a sturdy twill weave with diagonal ribbing having a high fabric gsm. But the ancient denim now is competed by a fabric known as jeans which has same properties as denim but used with various blends. The production of this fabric has been on an ever increasing demand since then.As far as manufacturing process of denim is considered, it is similar to that of grey fabric up to the process of weaving with only difference that in case of denim fabric, it is dyed at the stage of sizing where as in case of grey fabric, the decision regarding dyeing stage depends upon the finished product.

Objects of denim:-

Traditionally denim was developed as an industrial fabric. The object behind the development of denim was because of its property of durability and better serviceability. But sooner this fabric was accepted by the masses and was used by kids, women and the youth for regular apparel purposes.

Types of denim:-

While the original denim was 100% cotton serge material. But now we get denims in numerous varieties materials and features. There are five major varieties of denim:-

1. Dry Denim - This type of denim is given a dry and rough appearance and not washed after being dyed.

|

| Dry Denim |

|

| Selvage Denim |

|

| Stretch Denim |

|

| Poly Denim |

|

| Ramie Cotton Denim |

Since the introduction of denim in India in 1986, the industry has evolved continuously, witnessing a healthy positive growth for the past decade. India is the most competitively positioned country in the world for denim manufacturing and exports. Innovation has brought a constant change in the Indian denim industry. Stretch denims have proved to be an important innovation in the Indian denim market. Production of various blends has helped in the growing popularity of denim amongst kids and women driving the domestic market. The government’s anticipatory project of – Make in India is working as a growth catalyst. Biotechnology is changing the production of denim fabric as now focus of the present market is “ Sustainable Denim”.

Basis for Selection of Denim wear:-

Fibre properties :- Mostly medium and short length staple fibres of cotton and synthetic are used such as Lycra, polyester, etc.These fibres are preferably used because of their high strength and durable properties.

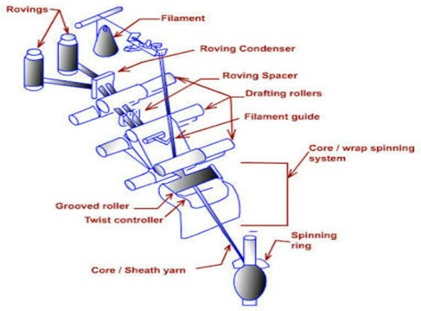

Yarn properties :- Room for coarser yarns having low twist.Less hairiness and good abrasion resistance.Soft to feel and good absorption to dyes. Impart fancy effect, slub yarn and multi count yarn is used.

Fabric properties:- Made of different twill weaves with high fabric gsm. Use of different blends as elastomers for stretch and other softer blends as rayon, modal for comfort and fit. Use of high luster yarns for better aesthetic properties.

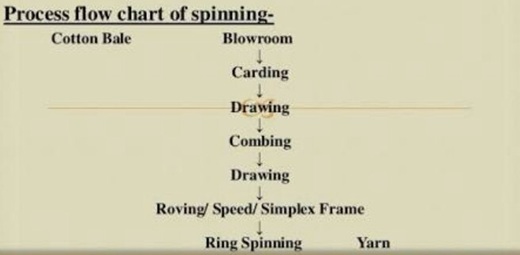

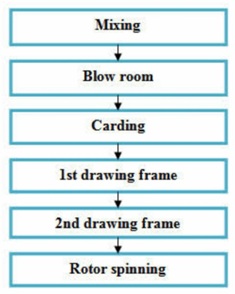

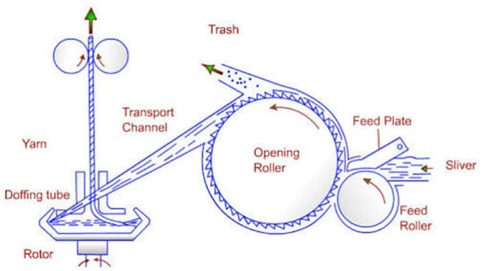

Spinning Technologies Used for Denim Wear:-

There are various spinning technologies used for the production of denim such as Ring spinning, Open end spinning, Twillo spinning, Friction spinning, etc. Of the above mentioned only ring spinning and open-end spinning are commercially used for the production of denim yarns.

Ring Spinning :- The yarn produced on ring spinning has high strength due to existence of high twist.But there is a limited production due to coarse count.The yarn has properties such as high hairiness, less stiffness.

|

| Ring Spinning |

|

| Open end Spinning |

Ring Spinning:- Automation in doffing, shifting of top delivery roller for reduction of spinning triangle, roving stop motion, individual spindle monitoring system, centralized suction and waste collection system.

|

| Ring Spinning |

|

| Open end Spinning |

Major focus areas of innovation and development are comfort, performance and environment friendliness. Use of special attachments on ring and rotor machines such as Amsler control to impart unique effects to the yarn. Use of multi-component in place of bi-component filament yarn is one such concept in the production of stretch denim yarns. Use of plied yarns on TFO to make denims. Use of slub yarns and multi-count yarns to impart fancy effects. Use of newly developed biochemical and cellulosic fibres such as Cupro, Modal, Promodal, Rayon and Tancel for softer blends of denim. Use of core spun with outstanding abrasion resistance and elasticity and etc. Blends of Bamboo and Hemp are under considerate experimentation for high end use denims. Use of engineered yarns has also found its way in the market because of the competition.

Conclusion:-

Denim is one of few things that has undergone a backward integration – as this fabric was developed for the lower working class, but with passage of time this fabric saw a lot of improvement and was accepted by the higher classes. Denim wear from an industrial fabric has made its way from work wear to be used in every type of garment and became a Fabric for all. It has become a sign of freedom and fashion for youth so there is going to be an ever increasing demand of denim. One of the major challenges of ring spinning is the existence of hairy yarn structure. Compact spinning provides reduced yarn hairiness, higher tenacity and improved yarn evenness. Rotor spinning were previously used only as the weft but now are used as denim warps too.By all these, we have been able to increase the production rate, enhance the varieties and quality range which has made denim – a fabric for all.

References:-

- Denim – A fabric for all By – Parmar Satsangi Prakash

- Denim – Manufacture, Finishing and Processing By – Roshan Paul

- Fibre2fashion magazines

- www.fibre2fashion.com

- A Practical guide to Ring Spinning By – W. Klein

- Spinning Manual of Rieter