Now You Know Comprehensive Study on Twill Weave

Sunday, 3 February 2019

Edit

Comprehensive Study on Twill Weave

Md. Enamul Haque

Department of Textile Engineering,

Khulna University of Engineering and Technology (KUET)

Khulna-9203, Bangladesh.

Email: enamul159@yahoo.com

Md. Enamul Haque

Department of Textile Engineering,

Khulna University of Engineering and Technology (KUET)

Khulna-9203, Bangladesh.

Email: enamul159@yahoo.com

Twill Weave

The order of interlacing which causes diagonal lines of warp and weft floats to be formed in the fabric is called twill weave. In the basic weaves of these diagonal lines are continuous but in some of their derivatives they may be broken or reversed periodically. The simplest possible repeat for a twill weave is 3 ends * 3 picks and there is no theoretical upper limit to the size of the repeat.

Features of twill weave

The main feature of twill weave are mention bellow -

Twill weaves can be classified from four points of view -

Features of twill weave

The main feature of twill weave are mention bellow -

- A twill weave is characterized by diagonal lines of warp and weft floats on the face of the fabric.

- Twill line may be from lower lift to upper right (Z-twill) or from lower right to upper lift(S-twill) corner.

- Smaller repeat twill is (3). It means take at least end and three picks produce twill weave.

- Three or more heald shaft are required for shedding.

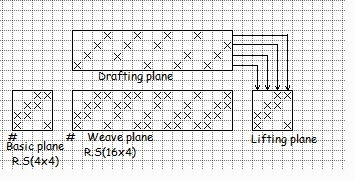

- Generally straight draft is used for twill weave besides this pointed or v draft is also used.

- Appearance it will design can be seen from both sides the fabric.

- Diagonal lines run at angle vary between (15-75) degree but in a continuous or regular twill is 45 degree.

- Twill lines are formed on both sides of cloths.

Twill weaves can be classified from four points of view -

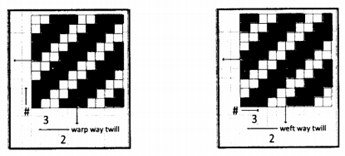

a) According to the way of construction

- Warp-way twill weave: 3/1 warp-way twill, etc.

- Weft-way twill weave: 2/3 weft-way twill, etc.

a) According to the way of construction

- Warp way twill weave : In warp way twill weave warp float run in the warp direction.

- Weft way twill weave : In weft way twill weave weft float run in the weft direction.

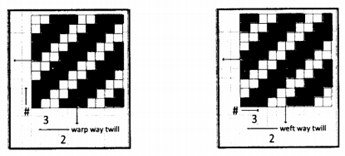

S-Twill :

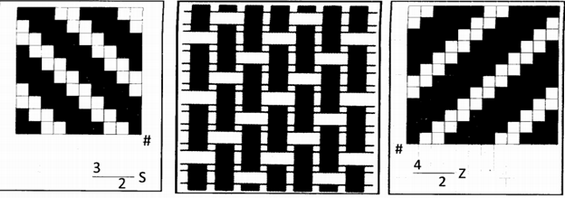

When the twill runs from the lower right to the upper left corner, the twill is known as a left-hand twill. It is produced by downward displacement of the interlacing points, if the starting point is bottom left corner or upward displacement of the interlacing points, if the starting point is bottom right corner. For example it is expressed by the formula number 3/2S, where S-indicate the direction of twill line.

|

| S-Twill |

When the diagonal line runs from the lower left corner to the upper right corner, the twill is known as a right-hand twill. About85% of all twill-woven fabrics are right-hand twill. The alignment of twill Iine is parallel to the middle portion of 'Z', so it is called Z - twill.

|

| Z-Twill |

Warp face twill weave :

Warp-faced twills have a predominance of warp yarns on the face of the fabric, with 2/1, 3/1, 3/2, 4/2 and so on. The top digit of the fraction line is higher than the bottom one, so it is called warp-face twill.

|

| Warp face twill weave |

Weft-faced twills have a predominance of weft yarns on the surface of the fabric with 2/3, ¾, ½, 2/4. And so on. The top digit of the fraction line is smaller than the bottom one, so it is called weft-face twill.

|

| Weft face twill weave |

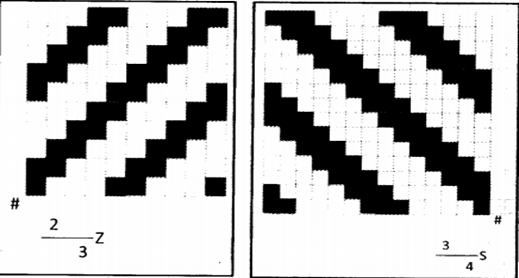

Even sided twills expose an equal amount of warp and weft yarn on each side of a fabric. In this case the top and bottom both are of the fraction line are same, so it is called double face twill.

|

| Double face twill weave |

Simple twill weave :

There are two types of simple twill, such as simple warp twill and simple weft twills. Each warp end is raised over or lowered under only one pick in the repeat, with pattern of ½, 1/3, ¼, 2/1, 3/1, 4/1, and so on. ½, 1/3, ¼, etc. are the simple weft twill and 2/1, 3/1, 4/1, etc. are the simple warp twill.

|

| Simple twill weave |

Each warp end is raised over or lowered under more than one adjacent pick in the repeat. Lf the warp and weft twill lines are of equal width, the fabric is double-faced. It is represented by the formula number of 2/3, 3/2, 4/4, 2/4, and so on.

Multiple twill weave :

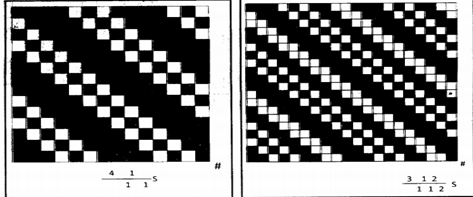

In each repeat, there are at least two warp twill lines or two weft twill lines of different width. If the prominency of warp yar is more than it is called warp-face multiple twill and the prominency of weft yarn is more than it is called weft-face multiple twill. If the prominency of both warp and weft yarns are same than it is called double-face multiple twill. Lt is represented by the formula number of , , and so on.

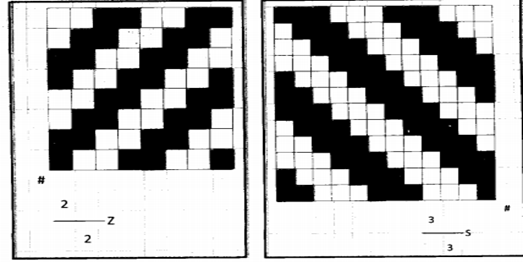

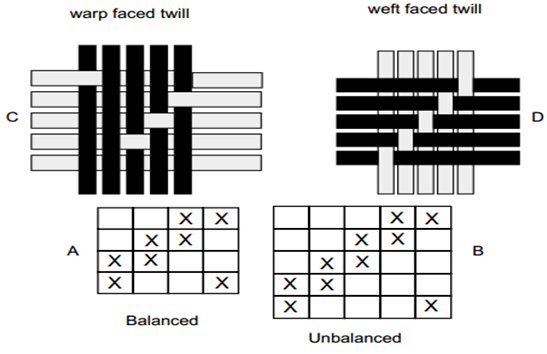

(e) Balanced and unbalanced twill

In these types of twills the warp and weft floats may be equal or unequal. In other words the twills may be of the reversible or irreversible types. Accordingly they may be known as balanced and unbalanced twills. Examples of balanced twills are 2/2, 3/3, 4/4, 5/5 etc. Examples of unbalanced twills are 2/3, 4/2, 5/3 etc. The 2/2 twill is popularly known as “Gaberdene” weave.

Factor Affecting the Prominence of Twill Weave:

The following factor affecting the prominence of twill weave -

1. Feature of weave

The prominence of twill line on feature of weave in the following ways;

It influence twill line as bellow:

More number of ends or picks per inch causes more prominent twill line.

4. Direction of twill line in relation to yarn twist direction:

When direction of twill on fabric is opposite to the direction of twist in yarn the twill line becomes more prominent and vice-versa.

Twill Angle

Twill angle is the angle which is produced by twill line with respect to the horizontal line. This twill angle depends on following factors.

Derivatives of Twill Weave

Derivatives of Twill Weave

There are many derivatives of twill are given bellow;

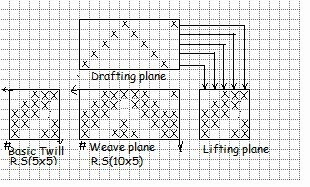

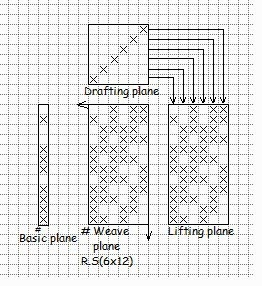

Vertical zigzag twill: When the reversal direction of twill line occur upon the weft yarn, it result a vertical zigzag twill, here the basic twill is extended in weft direction. Here the number of weft yarn in a repeat is double of the number of warp. In Vertical zigzag twill straight draft is used.

2. Hearing Bone Twill

This twill are constructed in a different manner from the ordinary zigzag twill. Though it also depend on reversal of twill direction.

Here reversal direction occurs after a middle line. Here at first the basic twill is drown then the number of central point is selected in zigzag twill. Rather in extended second half of basic twill the following matter happened.

When hearing bone twill is created by extending the basic twill in warp direction, horizontal hearing bone result in. The repeat size of horizontal herringbone is calculated from the regular or base twill weave like as horizontal zigzag weave. In this case the number of warp yarn in herringbone weave is double of the number of warp yarn of base twill and the number of weft yarn is same as base twill weave.

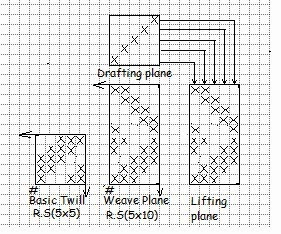

Vertical hearing bone twill:

When hearing bone twill is created by extending the basic twill in weft direction, vertical hearing bone result in. The repeat size of vertical herringbone is calculated from the regular or base twill weave like as vertical zig-zag weave. In this case the number of weft yarn in herringbone weave is double of the number of weft yarn of base twill and the number of warp yarn is same as base twill weave.

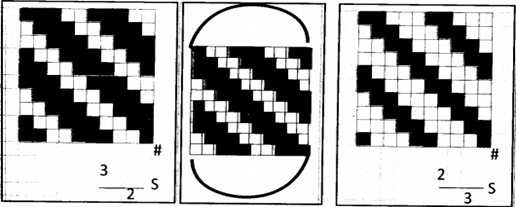

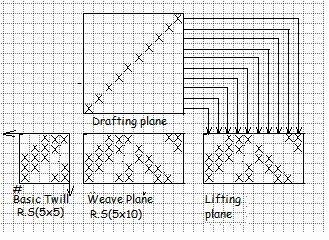

3. Diamond Design

It is a derivatives of twill weave. It constructed on the basis of zigzag twill principle. It is obtain by combining a horizontal and vertical zigzag twill. So here in the repeat the number of both warp and weft thread are double then that in basic twill. Diamond is a reversible design. So it may be divided into two equal parts in both vertical and horizontal axis. Pointed or V-drafting system is used to produce diamond design.

Diamond design geometrical about there vertical and horizontal axis. In this weave pointed draft is obtained.

To contract a diamond design at first the design repeat is selected. It the basic twill is 3 up 3 down, that is 6×6 in size, the repeat of design will be 12×12 in size.

Uses: Towel, Bed cover, Table cloth, Pillow cover etc.

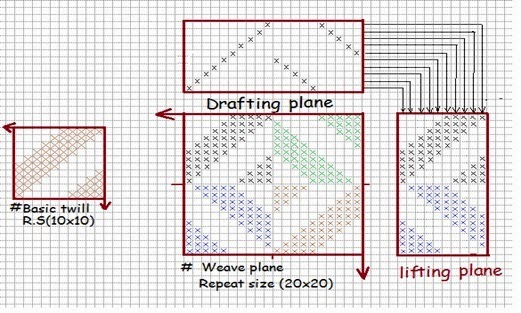

4. Diaper Design

This derivative of twill weave is created on the basis herring bone principle. This design is constructed by combining horizontal and vertical hearing bone twill.

In the repeat of a diaper design the number of warp and weft threads are two type more than that in its basic twill. So if the basic twill size is 8×8. Its diaper design repeat size will 16×16. In case of diaper design, Broken or straight draft is used

Use: Same diamond.

5. Broken Twill

6. Elongated Twill

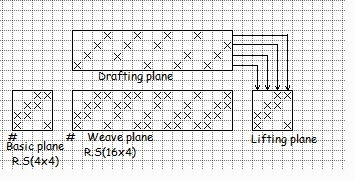

A peculiar form of twill, known as an elongated or steep twill, is obtained when the warp float of each thread rises two or more picks instead of one pick above the float of the preceding thread.

Normally the twill angle is 45 degree where the end and pick per unit area are equal .But in elongated twill, the twill angle more or less than 45 degree any twill design without twill angle.

Elongated twill can be formed in two different ways:

If the step number of elongated twill is two, then by taking only odd number of warp thread from the basic twill here the warp number in step twill will be equal to the basic twill.  (b) By selecting starting of elongated twill with a base line:

(b) By selecting starting of elongated twill with a base line:

Here at first a step number is to be selected. In such a way that the repeat of base line become devisable by that step number.

For example, for a twill with formula number the repeat size will be 14×14.If we select move number as 2 then in produced elongated twill the number of warp thread will be 7 and that of weft thread will be 7 in case of weft faced twill.

7. Stepped twill

These weaves are generated by introducing a step into the design after a certain number of ends or picks. At the step, every thread changes from up to down or vice versa. This are two type stepped twill-

(a)Warp way stepped twill:

There are two types of warp-way step twill. One is created in the same twill direction and another one is created by reversal of the twill direction.  Same twill direction: In the same twill direction step may be occur after the repeat or any desired number of thread.

Same twill direction: In the same twill direction step may be occur after the repeat or any desired number of thread.

Reversal of the twill direction: Same as horizontal herringbone twill weave.

(b) Weft way stepped twill:

There are also two types of weft-way step twill like as warp-way step twill weave. One is created in the same twill direction and another one is created by reversal of the twill direction.

Same twill direction: In the same twill direction step may be occur after the repeat or any desired number of thread like as warp-w ay step twill weave.

Reversal of the twill direction: Same as vertical herringbone twill weave.

8. Shaded Twill

By shaded twill we can create shade effect on fabric Shade effect can be produce in different way on the surface of the fabric. The shaded twill are of following type -

Single shaded twill:

Double shaded twill:

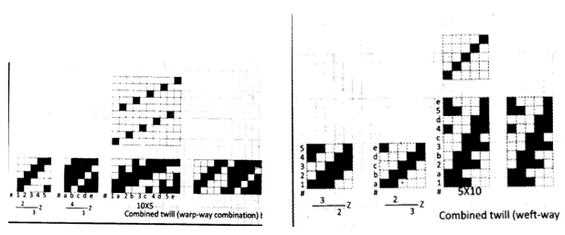

9. Combined twill

|

| Expanded twill weave |

In each repeat, there are at least two warp twill lines or two weft twill lines of different width. If the prominency of warp yar is more than it is called warp-face multiple twill and the prominency of weft yarn is more than it is called weft-face multiple twill. If the prominency of both warp and weft yarns are same than it is called double-face multiple twill. Lt is represented by the formula number of , , and so on.

|

| Multiple twill weave |

In these types of twills the warp and weft floats may be equal or unequal. In other words the twills may be of the reversible or irreversible types. Accordingly they may be known as balanced and unbalanced twills. Examples of balanced twills are 2/2, 3/3, 4/4, 5/5 etc. Examples of unbalanced twills are 2/3, 4/2, 5/3 etc. The 2/2 twill is popularly known as “Gaberdene” weave.

|

| Balanced and unbalanced twill |

The following factor affecting the prominence of twill weave -

1. Feature of weave

The prominence of twill line on feature of weave in the following ways;

- The twill of short floats less prominent twill line.

- The twill line of long float more prominent.

It influence twill line as bellow:

- Twill off course and soft twisted yarn→ More prominent twill line.

- Twill of fine and more twisted yarn→ Less prominent twill line.

More number of ends or picks per inch causes more prominent twill line.

4. Direction of twill line in relation to yarn twist direction:

When direction of twill on fabric is opposite to the direction of twist in yarn the twill line becomes more prominent and vice-versa.

Twill Angle

Twill angle is the angle which is produced by twill line with respect to the horizontal line. This twill angle depends on following factors.

- Ratio between EPI and PPI.

- Difference between warp and weft count.

- Rate of advancement it interlacement warp and weft.

There are many derivatives of twill are given bellow;

- Zigzag/waved/pointed twill weave.

- Hearing bone twill.

- Diamond design.

- Diaper design.

- Broken twill.

- Elongated design.

- Stepped twill.

- Shaded twill.

- Combined twill.

- Rearranged twill

- It is the simplest and one of the most important modifications of twill weave produced by reversing the direction of twill at suitable interval.

- A point is selected (usually the last warp is selected ) as the reversing point and so it is sometime call as point twill.

- In this twill pointed or straight draft is used.

- This twill is produced by combining S and Z twist.

- Horizontal zigzag twill.

- Vertical zigzag twill.

|

| Horizontal zigzag twill |

|

| Vertical zigzag twill |

This twill are constructed in a different manner from the ordinary zigzag twill. Though it also depend on reversal of twill direction.

Here reversal direction occurs after a middle line. Here at first the basic twill is drown then the number of central point is selected in zigzag twill. Rather in extended second half of basic twill the following matter happened.

- The floating point of first half become down in second half.

- The down of first half become floating in second half.

- Horizontal hearing bone twill.

- Vertical hearing bone twill.

When hearing bone twill is created by extending the basic twill in warp direction, horizontal hearing bone result in. The repeat size of horizontal herringbone is calculated from the regular or base twill weave like as horizontal zigzag weave. In this case the number of warp yarn in herringbone weave is double of the number of warp yarn of base twill and the number of weft yarn is same as base twill weave.

|

| Horizontal hearing bone twill |

When hearing bone twill is created by extending the basic twill in weft direction, vertical hearing bone result in. The repeat size of vertical herringbone is calculated from the regular or base twill weave like as vertical zig-zag weave. In this case the number of weft yarn in herringbone weave is double of the number of weft yarn of base twill and the number of warp yarn is same as base twill weave.

|

| Vertical hearing bone twill |

It is a derivatives of twill weave. It constructed on the basis of zigzag twill principle. It is obtain by combining a horizontal and vertical zigzag twill. So here in the repeat the number of both warp and weft thread are double then that in basic twill. Diamond is a reversible design. So it may be divided into two equal parts in both vertical and horizontal axis. Pointed or V-drafting system is used to produce diamond design.

Diamond design geometrical about there vertical and horizontal axis. In this weave pointed draft is obtained.

|

| Diamond design |

Uses: Towel, Bed cover, Table cloth, Pillow cover etc.

4. Diaper Design

This derivative of twill weave is created on the basis herring bone principle. This design is constructed by combining horizontal and vertical hearing bone twill.

|

| Diaper Design |

Use: Same diamond.

5. Broken Twill

- This is obtain by breaking the twill line of a regular twill. It is somewhat similar in appearance Zigzag twill.

- Broken twill can be obtained in different ways. At first basic twill is divided into two section, then the first section unchanged and the second section is reverse its order, that is to say if the basic twill is made up of 8 warp threads namely1,2,3,4,5,6,7,8 then its broken twill derivatives will obtain the order 1,2,3,48.7,6,5.

- Broken draft is used in broken twill.

|

| Broken twill |

A peculiar form of twill, known as an elongated or steep twill, is obtained when the warp float of each thread rises two or more picks instead of one pick above the float of the preceding thread.

Normally the twill angle is 45 degree where the end and pick per unit area are equal .But in elongated twill, the twill angle more or less than 45 degree any twill design without twill angle.

Elongated twill can be formed in two different ways:

- With the help of step number.

- By selecting starting of elongated twill with a base line.

If the step number of elongated twill is two, then by taking only odd number of warp thread from the basic twill here the warp number in step twill will be equal to the basic twill.

Here at first a step number is to be selected. In such a way that the repeat of base line become devisable by that step number.

|

| Elongated twill |

7. Stepped twill

These weaves are generated by introducing a step into the design after a certain number of ends or picks. At the step, every thread changes from up to down or vice versa. This are two type stepped twill-

(a)Warp way stepped twill:

There are two types of warp-way step twill. One is created in the same twill direction and another one is created by reversal of the twill direction.

Reversal of the twill direction: Same as horizontal herringbone twill weave.

(b) Weft way stepped twill:

There are also two types of weft-way step twill like as warp-way step twill weave. One is created in the same twill direction and another one is created by reversal of the twill direction.

Same twill direction: In the same twill direction step may be occur after the repeat or any desired number of thread like as warp-w ay step twill weave.

Reversal of the twill direction: Same as vertical herringbone twill weave.

8. Shaded Twill

By shaded twill we can create shade effect on fabric Shade effect can be produce in different way on the surface of the fabric. The shaded twill are of following type -

Single shaded twill:

- Shading effect becomes gradually deep from thin and after being deep it again starts to be thin and thus compute the whole repeat.

- It can be caused by continuous twill.

Double shaded twill:

- Shading effect becomes gradually deep from thin and after being deep it again starts to be thin and again becomes thin gradually and compute the whole repeat.

- These effects are produced from the regular multiple twill.

9. Combined twill

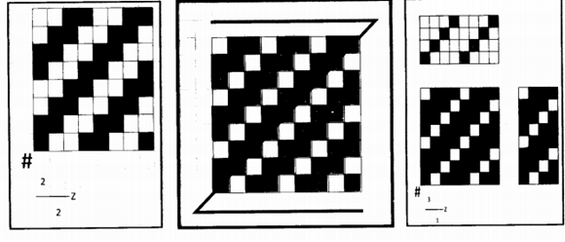

- Combined twill are formed by combination of two continuous twill.

- According to this combination, there are two types of combined twill, such as warp-way combined twill and weft-way combined twill.

- In combined twill no practically limitations exist and varieties of design can be produced.

- It may be both warp face and weft face.

- It is capable of producing compact and firm tertures.

- In warp way combined twill divided draft and weft way straight draft are produced.

- In case of equal no. of base twill : 6x6, 6x6; or 8x8, 8x8.

- In case of unequal no. of base twill : 4x4, 6x6; or 8x8, 6x6.

|

| Combined twill |

10. Rearranged twill

Rearrangement of twill is produced by the transposition of the original order of threads in the regular basic twill. The transposition may interrupt the continuation of twill line and thus may an effect of broken twill design. The twill can be constructed by –

One can rearrange weaves by changing the sequence of the warp ends.

The following figure represent 5 - end expanded weft twill 2/3 , rearranged as a steep or elongated twill by changing the warp sequence to every 2nd end.  Rearranging the yarn group wise

Rearranging the yarn group wise

With this type of rearrangement one divides the original weave into groups of two or more ends and changes their sequence e.g. by reversing it or arranging them in satin fashion.

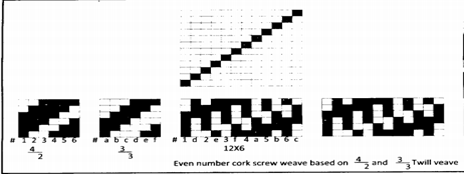

Cork screw weave

Cork screw weaves are a variety of rearranged twill. These weaves, also called diagonal ribs. The peculiar feature of corkscrew weaves is the combination of two or more distinct twill lines, which maybe of different colors. They are used for garment for which they are capable of producing firm and compact textures of greater strength, warmth and durability. They are of two kinds, such as

Even number cork screw is produced from two different regular base twill of the same repeat size. In this case the number of warp yarn in the repeat size of the resultant corkscrew weave will be the sum of the number of warp yarn of the base twill weave and the number of weft yarn is equal to the base twill.

Odd number corkscrew weave

Rearrangement of twill is produced by the transposition of the original order of threads in the regular basic twill. The transposition may interrupt the continuation of twill line and thus may an effect of broken twill design. The twill can be constructed by –

- Rearranging the yarn individually

- Rearranging the yarn group wise

- Cork screw weave

One can rearrange weaves by changing the sequence of the warp ends.

The following figure represent 5 - end expanded weft twill 2/3 , rearranged as a steep or elongated twill by changing the warp sequence to every 2nd end.

With this type of rearrangement one divides the original weave into groups of two or more ends and changes their sequence e.g. by reversing it or arranging them in satin fashion.

Cork screw weave

Cork screw weaves are a variety of rearranged twill. These weaves, also called diagonal ribs. The peculiar feature of corkscrew weaves is the combination of two or more distinct twill lines, which maybe of different colors. They are used for garment for which they are capable of producing firm and compact textures of greater strength, warmth and durability. They are of two kinds, such as

- Odd number corkscrew weave, and

- Even number cork screw weave.

Even number cork screw is produced from two different regular base twill of the same repeat size. In this case the number of warp yarn in the repeat size of the resultant corkscrew weave will be the sum of the number of warp yarn of the base twill weave and the number of weft yarn is equal to the base twill.

|

| Even number cork screw weave |

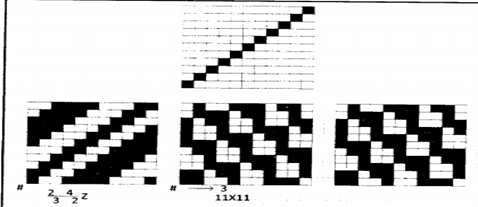

- Rearrangement of continuous twill is satin order

- Can be produced in both warp way and weft way

- Weave is formed from odd no of warp and weft yarn.

|

| Odd number corkscrew weave |

Advantages of twill weave

Twill weave are extensively used in manufacturing cloth for garments household cloth and industrial cloth.

- Twill weaves usually make fabrics closer in texture, heavier, and stronger than do plain weaves.

- It is possible to produce more fancy designs in twills than in plain weaves.

- In addition to their distinctive appearance and high strength, twill fabrics tend to show soil less readily than plain-weave fabrics.

- The major advantages of a twill fabric are that it is durable and wears well, resists soiling, and has good resistance to wrinkling.

- Twills are more expensive to produce than plain-weave fabric

- It is more difficult to clean than plain weave fabrics

- It usually has a right and wrong side which may make garment design difficult.

- Unless given special treatments, some uneven twill fabrics produce garments that are prone to twisting or skewing on the body after laundering.

Twill weave are extensively used in manufacturing cloth for garments household cloth and industrial cloth.

- Generally diamond, diaper and zigzag twill are used for making pillow, cover, screen, bed sheet, towel etc.

- Continuous twill are used for making fabric for shirting, suiting and panting(denim, gaberdine).

- For making various type of ornamental cloth, other derivatives of twill weave are used.

- Hearing bone twill are used in the cloth of suiting and overcoats.