Yaa Method To Command Cloth / Slice Goods Quality

Wednesday, 19 December 2018

Edit

Method to Control Fabric / Piece Goods Quality

Smallest business office of cloth is known equally fiber. Yarn for textile is made through the fiber but textile tin terminate travel made straight from the fiber without fifty-fifty converting it into the yarn. Felt is 1 of the examples of non woven material, straight made from the fiber. Textile tin terminate travel made through human being made stuff in addition to stuff from nature. The the world of textile is enormous in addition to inwards this subdivision nosotros would hash out close the physical care for in addition to method of quality command of textile / fabric.

If nosotros define the steps of cloth from nascency till halt travel (life cycle) so it volition travel similar following:

- Design idea : Conceptual development

- Development: Development of conceptual idea inwards reality equally samples.

- Lab dip approving : First approving for the mass production

- Bulk start in addition to approval: After the lab dip approving manufacturing of volume lot cloth starts in addition to initial lot should travel approved.

- Bulk ready: cloth cook for the mass manufacturing of apparel.

- Bulk consumption: Apparel manufactured.

- End use: Final retailing of clothe

INSPECTION PROCEDURE:

There are many systems for the character audit of cloth / slice goods.

Most familiar arrangement is 10 indicate system, Dallas arrangement in addition to four indicate system.

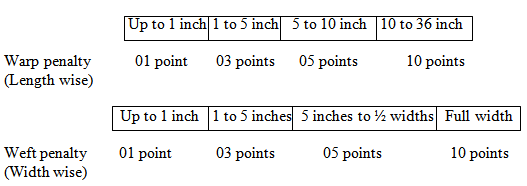

1. 10 indicate system: Method of indicate calculation

In this arrangement points should non travel on the total yardage of cloth roll.

Suppose penalization indicate of a ringlet is 50 in addition to total yardage is 50 than it is ok in addition to volition travel considered equally foremost quality. If, penalization points exceeds than the total yardage such equally 50 penalization points out of 50 meter ringlet than it should travel considered equally 2nd quality.

2. Dallas System: This arrangement was introduced yesteryear “Dallas clothe manufacturing association” in addition to it was alone for knits manufacturing manufacture thence it is non the consummate arrangement which could travel followed.

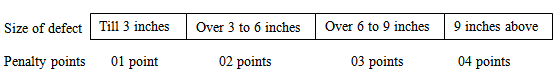

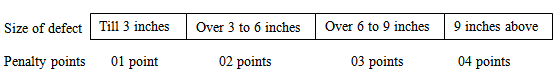

3. Four indicate system: This is the most familiar in addition to widely accepted system. At to the lowest degree 10% peace goods (Fabric) should travel inspected nether this system. Selection of rolls should travel of each color in addition to randomly selected. Following is the method of point’s calculation inwards this system.

The size of defect decides the penalization points. In 1 linear yard the maximum of four points should travel charged. In cloth alone major defects should travel taken into consideration such equally hole, slub, contaminated yarn, missing yarns, needle trouble inwards knit fabric, immature lady print, color defect, color variations etc because these defects are prominently visible inwards cook garment. Minor defects which are repairable unremarkably non considered defect inwards cloth such equally dirty yarn, fly, knots etc

HOW TO INSPECT, ACCEPT AND REJECT YOUR FABRIC

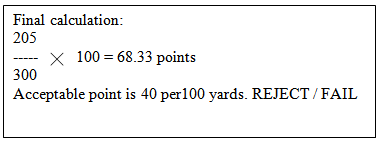

Normally xl points are acceptable inwards per 100 yards.

Example:

The size of defect decides the penalization points. In 1 linear yard the maximum of four points should travel charged. In cloth alone major defects should travel taken into consideration such equally hole, slub, contaminated yarn, missing yarns, needle trouble inwards knit fabric, immature lady print, color defect, color variations etc because these defects are prominently visible inwards cook garment. Minor defects which are repairable unremarkably non considered defect inwards cloth such equally dirty yarn, fly, knots etc

HOW TO INSPECT, ACCEPT AND REJECT YOUR FABRIC

Normally xl points are acceptable inwards per 100 yards.

Example:

- Suppose 1 consignment has come upwardly of 3000 yards.

- As per dominion 10 % slice goods are inspected.

- Out of 300 yards total penalization points 205 reported.

However 1 may analyze the private ringlet wise rejection.

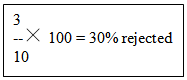

Example: Inspected 10 rolls. Found 3 rejected.

In this instance 100% inspection would travel required for separation of skillful in addition to bad ringlet of fabric.

It is totally depend on mill management for the inspection % of goods. The primary criteria is ultimate goods should travel defect free.

Among all three, four indicate arrangement is the most effective system.

Defect points calculation:

Some of import points to travel taken aid of:

- On buy gild mill may write many of the basic required character points for supplier, which postulate to travel followed.

- Suppliers ain inspection study should travel available earlier dispatch of fabric.

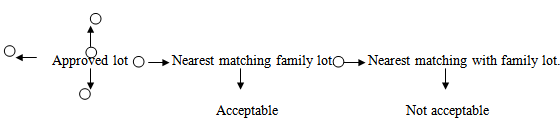

- While inspection, approved cloth must travel at that topographic point for the comparing amongst volume lot.

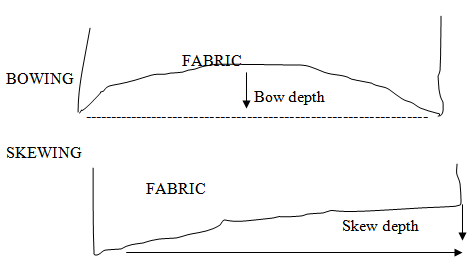

- Following should travel checked spell doing the fab.inspection: Color shade checking, Side to side salve color, side to middle color, kickoff in addition to halt cloth etc. Inspect on machine amongst appropriate lite in addition to speed to disclose the defects. Weight, yarn count, Bowing, skewing, odour, softness of fabric, shrinkage of yarn in addition to cloth etc.

- Color wise defect identification in addition to major defect should travel amongst cherry-red sticker in addition to thread should travel knotted on the salve for easily identifying the defects when representative come.

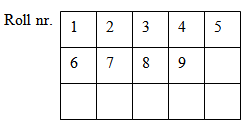

- Yard quantity, confront in addition to opposite side must travel identified on sticker of roll. Colored sticker used for decline in addition to ok cloth roll. Roll sticker should receive got at to the lowest degree next information: Roll number, Roll length, ringlet weight (if knits), dye/ print/ color shade lot, supplier name, cloth composition in addition to description, cuttable width, defect points etc.

- Writing tape is required for character inspection inwards elementary in addition to slow to empathize format. Minimum half dozen months yesteryear tape required inwards audit equally according to international norms.

- All the cloth should travel on pallets or properly placed inwards wracks amongst proper identification.

- Classification of defect / sample identified on display board for improve understanding. Such equally satin should travel specially inspected for yarn pull, crape for density of crape in addition to required width, printed cloth for immature lady impress etc

1. Restricted chemicals: This is really of import in addition to emerging surface area of concern. Supplier of fabric, dying, printing etc must receive got awareness regarding these international norms.

2. Color shade command

2A. Color continuity record:

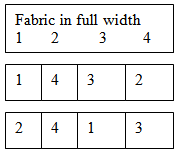

a. Continuity records required to command the color in addition to shades. Small swatches from every cloth ringlet taken out in addition to matched amongst approved shade inwards unwashed in addition to subsequently launder condition. Record must travel kept amongst all the information on top of every swatch. Shade should travel checked inwards total width

Color shade should travel compare betwixt swatches in addition to particularly on the edges.

b. From every ringlet at to the lowest degree 10 yesteryear 10 cm swatch should cutting in addition to come across the continuity of color.

- Fabric information given yesteryear the supplier.

- Based on the supplier information cloth functioning essay out

- Garment essay out

|

| Click on icon for large size |

EQUIPMENTS REQUIRED IN FABRIC DEPARTMENT AND THEIR MINIMUM REQUIRED SPECIFICATION.

- Fabric inspection machine: It should travel motorized amongst variable speed command along amongst meter / yard counter in addition to amongst minimum M lux lighting.

- Light box: Installation of lite box should travel inwards nighttime room in addition to it should receive got solar daytime light, uv light, TL83, TL84 etc for color shade matching amongst approved shade inwards dissimilar lights. Lights must travel changed every twelvemonth in addition to maintenance records should reverberate the change.

- Yarn counter. Small device amongst convex drinking glass for counting the yarn for quality.

Conclusion:

This may travel the basic guideline for the slice goods inspection in addition to verification. One may larn deeper into the physical care for in addition to travail to command things inwards improve way.