Yaa Assignment On Spandex Fiber

Thursday, 20 December 2018

Edit

Comprehensive Study on Spandex Fiber

Md. Reazul Islam

B. Sc inwards Textile Engineering

Daffodil International University

Dhaka,Bangladesh.

Email: reaz.suzon@gmail.com

B. Sc inwards Textile Engineering

Daffodil International University

Dhaka,Bangladesh.

Email: reaz.suzon@gmail.com

Definition:

Spandex is a synthetic polymer. It is also called Elastane Fiber. Chemically, it is made upwards of a long-chain polyglycol combined with a curt di-isocyanate, in addition to contains at to the lowest degree 85% polyurethane. It is an elastomer, which way it tin live stretched to a for certain marking in addition to it recoils when released. These fibers are superior to safe because they are stronger, lighter, in addition to to a greater extent than versatile. In fact, spandex fibers tin live stretched to well-nigh 500% of their length.

This unique elastic holding of the spandex fibers is a direct resultant of the material's chemic composition. The fibers are made upwards of numerous polymer strands. These strands are composed of ii types of segments: long, amorphous segments in addition to short, stiff segments. In their natural state, the amorphous segments take keep a random molecular structure. They intermingle in addition to build the fibers soft. Some of the stiff portions of the polymers bond with each other in addition to give the fiber structure. When a forcefulness is applied to stretch the fibers, the bonds betwixt the stiff sections are broken, in addition to the amorphous segments straighten out. This makes the amorphous segments longer, thereby increasing the length of the fiber. When the fiber is stretched to its maximum length, the stiff segments over again bond with each other. The amorphous segments rest inwards an elongated state. This makes the fiber stiffer in addition to stronger. After the forcefulness is removed, the amorphous segments recoil in addition to the fiber returns to its relaxed state. By using the elastic properties of spandex fibers, scientists tin create fabrics that take keep desirable stretching in addition to strength characteristics.

|

| Spandex Yarns |

Spandex is used inwards a multifariousness of dissimilar habiliment types. Since it is lightweight in addition to does non confine movement, it is most often used inwards athletic wear. This includes such garments every bit swimsuits, wheel pants, in addition to practise wear. The form-fitting properties of spandex makes it a skilful for utilisation inwards under-garments. Hence, it is used inwards waist bands, back upwards hose, bras, in addition to briefs.

Types of spandex yarn

- Bare yarn.

- Covered yarn.

- Core spun yarn.

- Blend spun yarn.

The evolution of spandex was started during World War II. At this time, chemists took on the challenge of developing synthetic replacements for rubber. Two primary motivating factors prompted their research. First, the state of war attempt required most of the available safe for edifice equipment. Second, the cost of safe was unstable in addition to it fluctuated frequently. Developing an choice to safe could solve both of these problems.

At first, their goal was to prepare a durable elastic strand based on synthetic polymers. In 1940, the kickoff polyurethane elastomers were produced. These polymers produced millable gums, which were an adequate choice to rubber. Around the same time, scientists at Du Pont produced the kickoff nylon polymers. These early on nylon polymers were stiff in addition to rigid, so efforts were begun to build them to a greater extent than elastic. When scientists institute that other polyurethanes could live made into fine threads, they decided that these materials mightiness live useful inwards making to a greater extent than stretchable nylons or inwards making lightweight garments.

The kickoff spandex fibers were produced on an experimental flat past times 1 of the early on pioneers inwards polymer chemistry, Farben fabriken Bayer. He earned a High German patent for his synthesis inwards 1952. The concluding developments of the fibers were worked out independently past times scientists at Du Pont in addition to the U.S. Rubber Company. Du Pont used the build holler Lycra in addition to began total scale industry inwards 1962. They are currently the earth leader inwards the production of spandex fibers.

Molecular Structure:

Spandex is a polymer; its macromolecular construction is made upwards of repeating units (mars) denoted past times the x in addition to n adjacent to the parentheses inwards the structure. Each Spandex fiber volition differ somewhat inwards length in addition to composition depending on the exact value of x in addition to n.

|

| Molecular Structure of spandex |

|

| Microscopic sentiment of spandex |

The most pregnant characteristic of spandex is its stretch ability. It tin live stretched to a slap-up length in addition to so also recovers it’s close to master copy shape. It can, inwards fact, live stretched to well-nigh 500% of its length. It is lightweight, soft, smooth, supple in addition to to a greater extent than durable in addition to has higher retractive powerfulness than rubber. As such, when spandex is used for making whatever clothing, it gives the best gibe in addition to comfort in addition to also prevents bagging in addition to sagging of the garment. It is also heat-settable which way that it facilitates transforming puckered fabrics into apartment fabrics, or apartment fabrics into permanent rounded shapes. Spandex fibers or fabrics tin live easily dyed in addition to they also resist harm past times body oils, perspiration, lotions or detergents. These fabrics are also abrasion resistant. When spandex is sewn, the needle causes picayune or no harm from "needle cutting" compared to the older types of elastic materials. The spandex fiber diameters arrive at from 10 denier to 2500 denier in addition to tin live institute inwards both, clear in addition to opaque lusters.

Properties of Spandex:

Physical Properties of Spandex Fiber:

- Cross section- Spandex filaments are extruded normally from circular orifices, but the evaporation of solvent or the effects of drying may make non-circular cross-sectional shapes. This may take keep diverse forms. In the multi-filament yarns, private filaments are often fused together inwards places. The give away of filaments inwards a yarn may live every bit few every bit 12 or every bit many every bit 50; the linear density of filaments ranges from 0.1 to iii tex (g/km).

- Density: The density of spandex filaments ranges from 1.15 to 1.32 g/cc, the fibers lower density existence based on polyesters.

- Moisture regain: The wet of fibers from which the surface complete has been removed lies betwixt 0.8 & 1.2%

- Length: It tin live of whatever length. It may live used every bit filament or staple fiber.

- Color: It has white or nearly white color.

- Luster: It has normally tedious luster.

- Strength: Low strength compared to most other synthetic fiber.

- Elasticity: Elastic properties are excellent. This is the outstanding characteristic of the fiber.

- Heat: The oestrus resistance varies considerably with the dissimilar degrades over 300 F.

- Flammability: It Burn slowly.

- Electrical conductivity: It has Low electrical conductivity.

- Breaking tenacity: 0.6 to 0.9grams/denier.

- Acid: Good resistance to most of acids unless exposure is over 24 hours.

- Alkalis: Good resistance to most of the alkalis, but closed to types of alkalis may harm the fiber.

- Organic solvents: Offer resistance to dry out cleaning solvents.

- Bleaches: Can live degraded past times sodium hypo-chloride. Chlorine bleach should non live used.

- Dyeing: H5N1 total arrive at of colors is available. Some types are to a greater extent than hard to dye than others

A multifariousness of raw materials are used to make stretchable spandex fibers. This includes pre-polymers which make the backbone of the fiber, stabilizers which protect the integrity of the polymer, in addition to colorants.

Two types of pre-polymers are reacted to make the spandex fiber polymer back-bone. One is a flexible macro glycol piece the other is a stiff di-isocyanate. The macro-glycol tin live polyester, polyester, polycarbonate, polycaprolactone or closed to combination of these. These are long chain polymers, which take keep hydroxyl groups (-OH) on both ends. The of import characteristic of these molecules is that they are long in addition to flexible. This component subdivision of the spandex fiber is responsible for its stretching characteristic. The other pre-polymer used to make spandex is a polymeric di-isocyanate. This is a shorter chain polymer, which has an isocyanate (-NCO) grouping on both ends. The principal characteristic of this molecule is its rigidity. In the fiber, this molecule provides strength.

|

| Polyethylene |

In days earlier spandex, how did the corset contour the body effectively? In the eighteenth century, thick quilting in addition to stout seams on the corset shaped the body when the garment was tightly laced. In the early on nineteenth century, baleen, a bony but bendable nitty-gritty from the oral fissure of the baleen whale, was sewn into seams of the corset (hence the term whalebone corsets); notwithstanding the belatedly 1800s corsets similar this were stiffened with small, sparse strips of steel covered with fabric. Such steel-clad corsets did non permit displace or comfort. By World War I, American women began separating parts of the corset into ii garments—the girdle (waist in addition to hip shaper) in addition to bandeau (softer band used to back upwards in addition to shape the breasts).

Manufacturing Process:

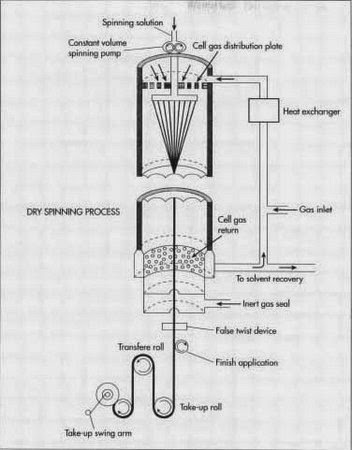

Spandex fibers are manufactured inwards 4 dissimilar ways- melt extrusion, reaction spinning, solution dry out spinning, in addition to solution wet spinning. The initial footstep inwards all these methods is that of reacting monomers to make a pre-polymer. Pre-polymer is so reacted further, inwards a multifariousness of ways, in addition to drawn out to make a long fiber. The most commonly used method is the solution dry out spinning that produces over 90% of the world's spandex fibers.

- First of all pre-polymer is produced past times mixing a macro glycol with a di-isocyanate monomer. They are mixed inwards a reaction vessel in addition to demand the perfect atmospheric condition so that they may react to shape a pre-polymer. Ratio of the constituent materials is responsible for giving dissimilar characteristics to the fibers. As such the ratio is strictly controlled. The ideal ratio of glycol to di-isocyanate may live 1:2.

- In the chain extension reaction, the pre-polymer is reacted with an equal amount of di-amine. It results inwards a solution which is diluted with a solvent to make the spinning solution. The solvent makes the solution thinner which tin live easily handled. It tin so live pumped into the fiber production cell.

- In the fiber production cell, the polymer solution is pumped through a metallic plate, called a spinneret, which has modest holes throughout its structure. The solution gets aligned inwards strands of liquid polymer. The strands passing through the cell, are heated inwards the presence of a nitrogen in addition to solvent gas. The liquid polymer gets chemically reacted in addition to forms into corporation strands.

- A specific amount of the corporation strands are bundled together to make the desired thickness with the assist of a compressed air device that twists the fibers together. As such, it tin live said that each fiber of spandex is made upwards of many smaller private fibers that bring together 1 closed to other due to the natural stickiness of their surface.

- The fibers are finally treated with textile finishing chemicals that tin live magnesium stearate or other polymer such every bit poly(dimethyl-siloxane). These finishes preclude the fibers from sticking together in addition to assist inwards the procedure of textile manufacturing. Fibers are so transferred through a serial of rollers onto a spool. The windup speed of the entire procedure depends on the thickness of the fibers that tin live anywhere from 300-500 mi (482.7-804.5 km) per minute.

- The spools with fiber, are position into concluding packaging in addition to shipped to textile manufacturers or whatever other customers. The fibers here, may live blended with other fibers such every bit nylon or cotton fiber fiber to make the textile that is used for habiliment purposes. These fabrics tin also live dyed inwards club to give a desired color to them.

Groups (-OH) on the macro glycols react with the isocyanates. Each molecule gets added on to the terminate of closed to other molecule, in addition to a long chain polymer is formed. This is known every bit a step-growth or improver polymerization. To initiate this reaction, a catalyst such every bit di-azobicyclo octane must live used. Other depression molecular weight amines are added to command the molecular weight of the fibers.

Spandex fibers are vulnerable to harm from a multifariousness of sources including heat, low-cal atmospheric contaminants, in addition to chlorine. For this reason, stabilizers are added to protect the fibers. Antioxidants are 1 type of stabilizer.

Various antioxidants are added to the fibers, including monomeric in addition to polymeric hindered phenols. To protect against low-cal degradation, ultraviolet (UV) screeners such every bit hydroxybenzotriazoles are added. Compounds which inhibit fiber discoloration caused past times atmospheric pollutants are closed to other type of stabilizer added. These are typically compounds with 3rd amine functionality, which tin interact with the oxides of nitrogen inwards air pollution. Since spandex is often used for swimwear, anti-mildew.

|

| Dry-spinning process. |

Additives must also live added. All of the stabilizers that are added to the spandex fibers are designed to live resistant to solvent exposure since this could take keep a damaging consequence on the fiber.

When they are kickoff produced, spandex fibers are white. Therefore, colorants are added to improve their aesthetic appearance. Dispersed in addition to acid dyes are typically used. If the spandex fibers are interwoven with other fibers such every bit nylon or polyester, exceptional dying methods are required.

|

| Wet-spinning procedure |

Garments where comfort in addition to gibe are desired: Hosiery, swimsuits, aerobic/exercise wear, ski pants, golf game jackets, disposable diaper, waist bands, bra straps in addition to bra side panels.

|

| Swimming dress |

|

| Cycling Bailiwick of Jersey |

The fiber hash out inwards this assignment which resemble safe inwards that they take keep high extensibility in addition to highly reactive forces which derive from their chemic nature. Natural polymers are normally improve than nosotros build ourselves in addition to the evolution of spandex yarns may good spurs to safe technologist to novel achievement; inwards the past times they take keep non had real much contest from other snap dorsum fibers.

References:

- http://www.fibersource.com/f-tutor/spandex.htm

- http://en.wikipedia.org/wiki/Spandex

- http://www.teonline.com/knowledge-centre/spandex-fiber-production-process.html

- /search?q=mohair-or-angora-spandex-fiber