Now You Know Scope of Seam Engineering to Increase the Seam Strength by Controlling Different Parameters (Part-3)

Friday, 1 June 2018

Edit

Scope of Seam Engineering to Increase the Seam Strength by Controlling Different Parameters (Part-3)

Authors: MD. Momenur Rahman,

Kazi Mustafijur Rahman,

Rabeya Siddiqua

Atish Dipankar University of Science and Technology

Dhaka, Bangladesh

Authors: MD. Momenur Rahman,

Kazi Mustafijur Rahman,

Rabeya Siddiqua

Atish Dipankar University of Science and Technology

Dhaka, Bangladesh

Previous Part

Result Overview

There are various parameters of sewing thread including its fiber type, construction, finish, size, ply & TPI, which affect the seam quality.

These parameters will be discuss following :

Various fabric properties like Cover factor, GSM, Thickness, Strength, Extensibility etc.

Human Factor:

- From the experimental work, it’s concluded that the usage of thicker threads did not always give better strength and the seam appearance was also poor.

- A combination of finer thread with moderate strength and a medium level of stitch density according to fabric weight category provided an effective result for both seam appearance and strength.

- Sewing Thread Size/Ticket Number, GSM, SPI &SPM is the main considerable point of the thesis. Change in those parameters seam strength is changed.

- The use of low and medium stitch density gave better results in terms of seam strength.

- In the prediction, thread tensile strength, extensibility and size were selected in most of the equations.

- Thread properties play an important role in determining the quality of seam.

- The equations have not been tested with other types of sewing threads since threads used for this study are commonly used in the apparel industry.

- Other types of stitches and seams could be used to sew the fabrics and analysis on their seam performance could be done.

- For this research, only single stitching was used; another possible research area is to use double stitching.

There are various parameters of sewing thread including its fiber type, construction, finish, size, ply & TPI, which affect the seam quality.

These parameters will be discuss following :

- Thread Fiber Type (seam strength highest for 100% spun polyester, average for cotton/polyester blend & lowest for 100% cotton).

- Thread Construction (seam strength highest for core spun yarn; 100% synthetic fiber shows more seam strength).

- Thread Finish (mercerized threads shows more seam strength than any soft cotton threads of the same fiber type and size ).

- Thread Ply (the more the thread ply, the more the seam strength is)

- TPI (the more the TPI, the more the seam strength is).

Effect of Thread size (Ticket Number) on seam strength

Graphical Expression

|

| Data table |

- The numerical expression of sewing thread fineness or coarseness is “Ticket number”. It is equal to three times the metric count of the thread.

- The more the ticket number, the high the seam strength is.

Various fabric properties like Cover factor, GSM, Thickness, Strength, Extensibility etc.

In the following sections these fabric properties are discussed in brief:

- Cover Factor (the more the cover factor, the less the seam strength is, the less the cover factor, the more the seam strength is).

- Fabric Weight(light fabric shows less seam strength than heavy fabrics).

- Fabric Thickness (the more the fabric thickness, the more the seam)

- Strength is & less seam efficiency)

- Fabric Strength (the more the fabric strength, the more the seam strength is & less seam efficiency)

- Fabric extensibility (the more the fabric extensibility, the more the seam strength is & less seam efficiency).

Effect of GSM on seam strength

Graphical Expression

Related:

|

| Data table |

- GSM means “Gram Per Square Meter”.

- It is the weight of fabric in gram per one square meter.

- By this we can compare the fabrics in unit area which is heavier and which is lighter.

- In a certain point, when GSM increases seam strength increase & over the time seam strength decreases though GSM increase.

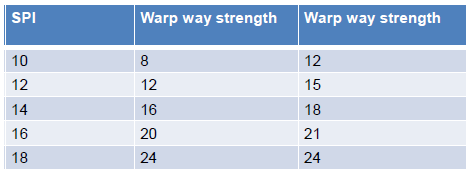

Graphical Expression

|

| Data table |

- Stitch density is specified as the number of stitches per inch (SPI).

- Higher stitches per inch (SPI) means short stitches; and lower SPI means long stitches.

- The greater the SPI in a seam, the greater the seam strength is & the lower the SPI in a seam, the lower the seam strength is.

Effect of stitch per minute (SPM) on seam strength

Graphical Expression

Effect of other factors on seam strength Graphical Expression

|

| Data table |

- Modern sewing machine speed can reach up to 5,500 stitches a minute.

- The fact is that, in a high speed sewing machine the movement of the sewing needle is higher that generates heat.

- This creates seam damage problem that causes of poor seam efficiency and appearance in a garment.

Human Factor:

- If the operator is lacking in skill, seam problems will be generated during sewing.

- Excessive or improper handling and positioning of the fabric parts during sewing lead to seam puckering.

- If the operator is unable to handle the sewing machine properly, there is a chance of seam damage due to frequent needle breakage.

- All environmental problems reduce the concentration and skill of the operator to work.

- Due to poor concentration and reduction of the skill, the operator cannot properly handle the garment parts during stitching.

- High humidity and temperature also reduced the strength of sewing thread during sewing that produce poor seam strength.

- For the analysis of the seam strength, transverse loading was used for this study where the loading was across the seam and the effect of thread strength was analyzed. For future work, the seam strength test could also be done on longitudinal loading where the load is parallel to the seam.

- The performance of seam can also be widened for weft and bias directions of sewing for both seam appearance and strength analysis. For the current study, only the warp direction of sewn fabrics was analyzed since this is the most common practice in the industry.

- ü Other types of stitches and seams could be used to sew the fabrics and analysis on their seam performance could be done. For this research, only single stitching was used; another possible research area is to use double stitching.

Sumber http://textilelearner.blogspot.com