Now You Know Manufacturing Process of Carbon Fiber

Monday, 4 February 2019

Edit

Manufacturing Process of Carbon Fiber

Anup Kumar Mohanta

Dept. of Textile Engineering

College of Engineering and Technology,

Bhubaneswar, Odisha, India

Email: anup.unlimited.007@gmail.com

Dept. of Textile Engineering

College of Engineering and Technology,

Bhubaneswar, Odisha, India

Email: anup.unlimited.007@gmail.com

CARBON FIBER:

Carbon fibers are manufactured from two pre cursors known as PAN (poly acrylonitrile) and pitch.

FROM PAN:

- PAN contains highly polar C-N groups that are randomly arranged on either side of the chain.

- Carbon filaments are wet spun from a solution of PAN and stretched at an elevated temperature during which the polymer chains are aligned in the filament direction. Then the filament are heated at 200 to 300 0C for a few hours.

|

| Structure of carbon fiber |

- At this stage the C-N groups located on the same side combine to form a more stable and rigid ladder like structure and some of the CH2 groups are oxidized.

- In the next stage the PAN filaments are carbonized by heating at a controlled rate between 1000 to 2000 0C in an inert atmosphere.

- Tension is maintained on the filament to prevent shrinkage and to improve molecular orientation.

- Subsequently the carbonized filaments are heated above 2000 0C, where their structures becomes more oriented and turns towards a true graphite form with increasing heat treatment temperature.

- At this stage the graphitized filaments attain a high tensile modulus, but their tensile strength may be relatively low.

- Tensile strength can be increased by hot stretching above 2000 0C.

- Pitch is a byproduct of petroleum refining, and is a lower cost raw material than PAN.

- The carbon atoms in pitch are arranged in low molecular weight aromatic ring patterns.

- Heating to temperature above 300 0C polymerizes these molecules into long two dimensional sheet like structure.

- The highly viscose state of pitch at this stage is called mesophase.

- Pitch filaments are produced by melt spinning the mesophase pitch through a spinneret.

- The filaments are cooled to freeze the molecular orientation and then heated between 200 to 300 0C in oxygen atmosphere to stabilize them and make them infusible.

- In the next step the filaments are carbonized at 2000 0C.

- Rest of process of transferring the structure to graphitic form is similar to that followed for PAN precautions.

|

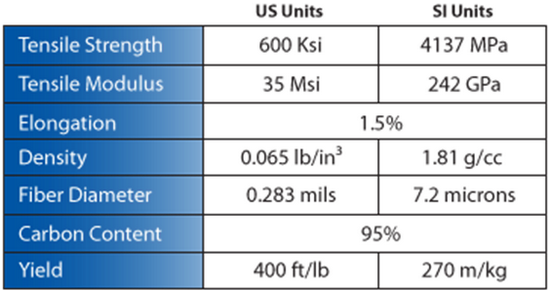

| Standard Fiber Properties |

Carbon fibers are used in the following fields: Aerospace, sporting goods, automobiles, wind turbine blades, military, medical applications and many more fields.