Yaa Spunbonding Method For Nonwoven Textile Production

Monday, 17 December 2018

Edit

Spunbonding Method for Nonwoven Fabric Production

Spunbonding:

Spunbonding is a procedure yesteryear which fabrics are produced straight from a thermoplastic polymer such equally polyester, nylon, polypropylene, or polyethylene. The molten polymer is extruded through a spinneret, cooled slightly inwards the air, too pose on a moving conveyor belt to cast a continuous web. As the spider web cools, the fibers bond.

Spunbonding Method for Nonwoven Production

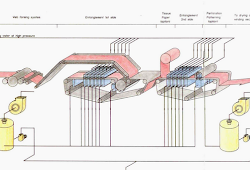

Spunbonding method is used for man-made filament fibers that melt nether heat, such equally polyester. Spunbond fabrics are produced yesteryear depositing extruded, spun filaments onto a collecting belt inwards a uniform random fashion followed yesteryear bonding the fibers. Spunbond fabrics are characterized yesteryear tensile, tear, too outburst strengths, elongation-to-break, weight, thickness, porosity too stability to estrus too chemicals. Spunbond products are employed inwards rug backing, geotextiles, too disposable medical/hygiene products. Since the stuff production is combined amongst fiber production, the procedure is mostly to a greater extent than economical than when using staple fiber to brand nonwoven fabrics.  |

| Web forming yesteryear the Spunbonding method |

Related:

Fabrics made yesteryear this procedure include Mirafi 140, made from nylon too polypropylene; Celestra polypropylene; Reemay polyester; Tyvek polyethylene; Typar polypropylene; Bondtex polyester; Cerex nylon; too Bidim polyester.